- Joined

- Nov 25, 2015

- Messages

- 8,333

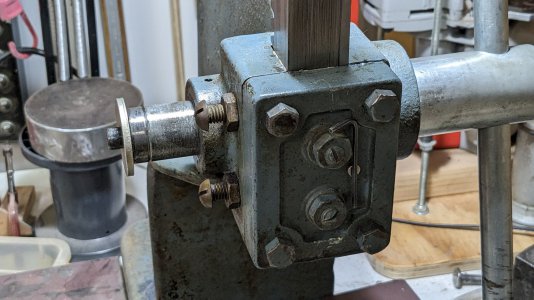

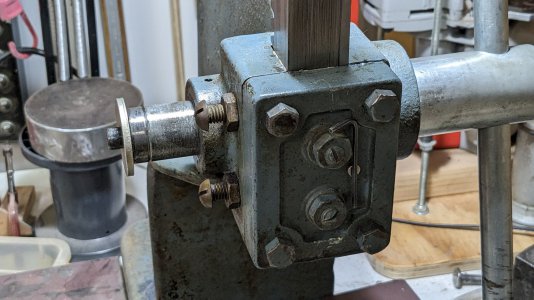

Ok, that was easy. The shaft on the end was the size of a 6203 bearing I think, didn't look. Just grabbed it thinking it would fit. I had an old frozen one by the presses for assisting. drilled and tapped the shaft for a 5/16 - 18, made an aluminum sleeve to match the bearing and screw.

Easy The only thing I might change is making a cover to protect the end of the shaft from dust/dirt/grit so it doesn't chew up the bore.

Easy The only thing I might change is making a cover to protect the end of the shaft from dust/dirt/grit so it doesn't chew up the bore.