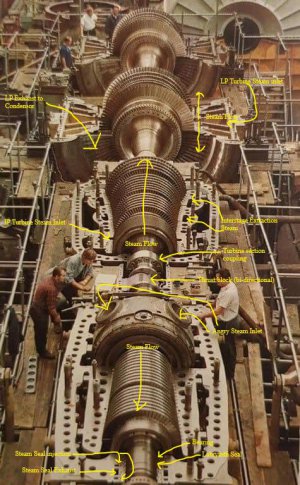

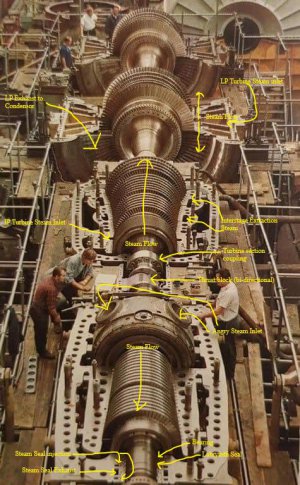

For one who doesn't know, perhaps a brief run through how it works?

We know that turbines are operated at speeds some multiple of 50Hz or 60Hz, but I am not sure what would be the indicator. Here I am guessing it is a choice between 1800rpm and 3600rpm based on the size of the kit compared to the men.

Is the part around it with pipe entries, in the foreground near the men, some kind of giant cooled bearing?

Is the steam first put in somewhere between the nearest two turbine blade sets?

How do the two much bigger parts farther back near the top of the picture work. Is that a lower pressure turbine?

Regardless, one has to be impressed at what it must have taken to face those mating srfaces, and drill all those holes!

Shore!

Speed of the turbine is designed around both the quality and quantity of steam available, as well as the generator it's self. In the US, power is delivered at 60Hz. Given that a cycle is considered 0 point, positive peak, 0 point, negative peak, 0 point, We need two poles to pass by to get a cycle, one + and one -. It makes sense that poles on the generator will be in pairs, so for this particular turbine, the generator would have 2 poles. Frequency = NP/120 (where N is speed in RPM, and P is number of poles). Typically plants that operate with Superheated steam in the first stage will run at 3600 RPM. It allows for more efficiency without having to worry about tearing up blading as much. An 1800 RPM turbine will be much MUCH larger than this. This will either be a coal fired plant (most likely), a gas fired plant, or a Boiling Water Reactor. Generally Pressurized Water Reactors don't operate in superheat.

As work is extracted from the steam, it decreases in steam quality, increases in volume, and decreases in pressure. This is why the blading gets larger as the flow path works through. As steam quality decreases, moisture content increases. At the speeds encountered inside a turbine, this moisture is bad. It will erode the blading as it impacts it. To alleviate this to a degree, a fraction of the steam is drawn off at certain points, hopefully taking a good deal of the moisture with it, and will be used to heat up feedwater going into the boiler/reactor, thereby saving efficiency while protecting the turbine. At the inlet, depending on the throttle setting (giant valves, not in this picture), the pressure is likely north of 1000 PSI. At the exhaust of the LP turbines, pressure will actually be at a fairly high vacuum (probably in the sub 5" mercury ballpark), and connected directly to the condenser. At these sizes, you have to be cognizant of the actual mass steam flow through the end stage blading. At 3600 RPM, the distal ends of the final stage LP blading are going to be red hot, and sufficient steam flow must be maintained to keep them from over heating. IE, don't run full speed no load for extended periods.

I can't tell who's turbine this is, it could be a CE, GE, Westinghouse, etc. Depending on who's it is, the generator could be at either end, but I generally expect it to be connected on the top end of this picture. On this one I'm guessing in general, probably 50% of the work is done by the HP turbine.

I could probably ramble a lot more on this, but I labeled some stuff using my EPIC paint skills, I hope this helps!