-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

And I thought my job was stressful! Lol

- Thread starter Martin W

- Start date

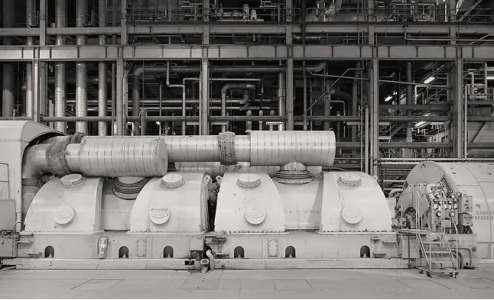

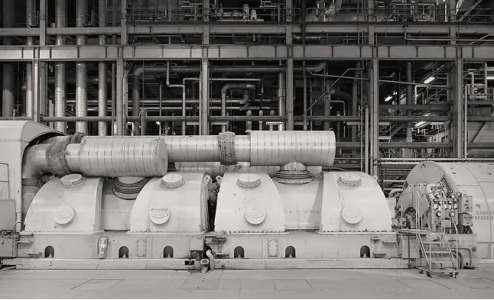

How many MW would that generate, perhaps 150?

1270 MWe

- Joined

- Apr 23, 2018

- Messages

- 6,559

Oh, that's just 1.7 million horsepower...1270 MWe

I worked for a short while at a 1200MW plant Lakeview and we had 8x 150MW and they were pretty big (see below). We had to do static exciter power system stability tests, imagine introducing a small step error into the feedback loop that controls the generator output, and then observe the response as the generator speed overshoots and then gets damped out (if everything is just right). Not for the faint of heart. We had a strobe on the shaft so we could see it in relative terms, pretty cool. These are small compared to the Bruce units, If I recall those are between 750 and 870MW.

Last edited:

We just got two new HP feedwaters heaters delivered today. I'll try to get a pic tomorrow.

The two main reasons we use hydrogen in the generator is the high heat transfer of H and reduce windage in the generator due to H's low density.

Generators are usually kept @~60psi. The H is cooled by hydrogen coolers inside the generator which have cooling water flowing in them.

And another interesting bit of info, something I find incredible. Well over 50% of total steam pressure is dropped on the first stage of the HP turbine.

The two main reasons we use hydrogen in the generator is the high heat transfer of H and reduce windage in the generator due to H's low density.

Generators are usually kept @~60psi. The H is cooled by hydrogen coolers inside the generator which have cooling water flowing in them.

And another interesting bit of info, something I find incredible. Well over 50% of total steam pressure is dropped on the first stage of the HP turbine.

It ain't small. The entire turbine/generator rotating weight is about 800 tons.Oh, that's just 1.7 million horsepower...

- Joined

- Apr 30, 2015

- Messages

- 11,335

That's one big margarita maker