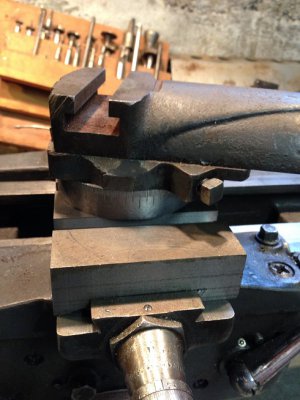

Something to note is the tiny cross slide size, there is actually pretty small surface area for bearing, and some of the forces put on it by parting are tremendous. One mod for that is to make a new cross slide and full length gib, personally I already have the iron for the project, in addition to much greater bearing area would be the addition of t slots. Drawback is the compound protractor.... as well as having to add the dovetail for the compound mount, I'm not fully decided on the route yet, but I think I will have a block bolted down for the quick change, and if I need to use a compound I can either cnc a protractor into it or swap out the slide for the stock one.

I have heard great things about this mod

Steve Shannon, P.E.

Steve Shannon, P.E.