OD grinding, wheel and work spin same direction:

http://www.kanabco.com/vms/other_grinding/other_grinding_06.html

Reason given:

"This so that the surface of the grinding wheel and the surface of the workpiece are moving in opposite directions at the point of contact. This also reduces the possibility of ride-up or jamming that can occur if they were rotating in opposite directions."

NEMES (a hobbyist group) published this in 1958:

http://neme-s.org/Model_Engineer_Files/2996-Grinding Rotation & Dressing.pdf

They agree, but give different reasons. Mostly for coolant and grinding sludge control. They also allow for the opposite, and have no serious objections other than making a mess by throwing coolant and grit upward.

https://en.wikipedia.org/wiki/Cylindrical_grinder

Pretty much agrees that the work should run against the wheel in the opposite direction, reason given is smoother work and less chance of jam-up.

I think if I kept looking, I could find more sources that give either answer, and give some of the same, and some different reasons.

Thank you Tony, You have confirmed my findings.

These articles say exactly the same thing as all the rest. The grinder and lathe run in opposite directions ( the instances showing them in the same direction has the grinding wheel to the rear of the work which is the same as opposite direction when the wheel is in front) They at least give a reason. So.... I will follow the directions when I experiment with my grinder after finishing it.

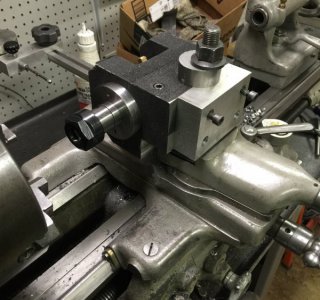

. There should be no movement or vibration on this setup as it mounts solid and directly on the saddle. Now I can finish the height adjustment.

. There should be no movement or vibration on this setup as it mounts solid and directly on the saddle. Now I can finish the height adjustment.

It has been pointed out to me ( a big thank you to Nelson Collar) that by mounting my grinder on the cross slide, I lost the ability to grind tapers which is very important ( to me anyways). So....... I will be making a major revision requiring some remachining of the base and mounting it on the compound. It is not too bad....I just have to modify the mounting post and mill at least a half inch off the base block. I'm glad someone thought of this and pointed it out so I an fix it quickly. I find it hard to believe I made such a simple error

It has been pointed out to me ( a big thank you to Nelson Collar) that by mounting my grinder on the cross slide, I lost the ability to grind tapers which is very important ( to me anyways). So....... I will be making a major revision requiring some remachining of the base and mounting it on the compound. It is not too bad....I just have to modify the mounting post and mill at least a half inch off the base block. I'm glad someone thought of this and pointed it out so I an fix it quickly. I find it hard to believe I made such a simple error