So trying to move forward my chuck will not hold my piece of scrap. It will also be very rough cut as all I have is a saws all. Not going to be pretty. Thinking hex cut close to dimensions and machine down

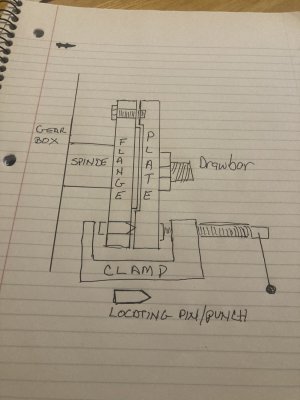

I was thinking of a mandrel in the check and drill tap hole and bolt piece to that ? I might not be clear on discription

I want to drill a hole in plate. Bolt it to round stock in chuck and maching the index for the lath spindle, drill and tap the holes mount the plate then machine the recess for the new chuck. Drill and tap holes for chuck.

I was thinking of a mandrel in the check and drill tap hole and bolt piece to that ? I might not be clear on discription

I want to drill a hole in plate. Bolt it to round stock in chuck and maching the index for the lath spindle, drill and tap the holes mount the plate then machine the recess for the new chuck. Drill and tap holes for chuck.