-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dipping my toes into turning

- Thread starter koenbro

- Start date

- Joined

- Feb 23, 2016

- Messages

- 424

I, somehow got the impressing you where a "Novice" on CNC. Seems not so you should be able to get things running.

I am MOST DEFINITELY a novice in machining, having started in 2020 with the mill. And more to the point of this thread, I have never used a lathe, have never even touched one: have not used a wood lathe either. The Eisen is my first ever exposure to turning, and I am barely familiar with the terminology ("compound" sounds exotic, etc). I am looking forward with great interest to learning about it. I have no idea about tool holding and so forth.

I got a Precision Matthews 728 mill in 2020 and it was the same story --- had never used a mill, never even seen one. Terms like "gibbs" were totally new. I learned a lot since, and now I can tram, correct nod, adjust backlash to some extent (still learning there) and can do Fusion 360 at a beginner intermediate level; @JimDawson has been very generous in guiding me with toolpaths. Have done some aluminum projects with simple shapes and I am getting more comfortable with the process; still lots of growth is needed. Steel has been frustrating so far; the machine is not very heavy or rigid even though I added maybe 300lbs(*) to it as the base and it is all bolted together and to the floor. But having converted it to CNC I learned a lot.

With the lathe I plan to use it in manual for the foreseeable future (apart from the ELS).

But I need a lot of advice and guidance. I am investigating what BXA toolpost to getm and then the basic toolset, using @davidpbest 's book and list of starter tooling.

What advice do you have regarding BXA QCTP? Thank you.

EDIT. I added a steel base that is 180lbs, filled it with 120lbs of sand, and have a granite countertop that is maybe another 100-150lbs. So total of 400-450 lbs added.

Last edited:

Most QCTP systems stick out a lot and make the tool post less rigid. That is a show stopper for me. For CNC turning a high repeatability is required but for manual turning, the tool "just" needs to be on center.

Use the tool post the lathe come's with. Buy some HSS turning tools, a HSS parting tool and learn how to (re)grind them. Get some POM, Brass, Aluminum and mild steel and learn turning by trial and error.

Then buy some cheap insert tools and break a lot of the inserts. Once you start wearing them out, it is (maybe) time for a better quality insert.

Like milling, most general values for feeds and speed don't work for your mill and will not work for your lathe. You have to figure out what works for you.

Use the tool post the lathe come's with. Buy some HSS turning tools, a HSS parting tool and learn how to (re)grind them. Get some POM, Brass, Aluminum and mild steel and learn turning by trial and error.

Then buy some cheap insert tools and break a lot of the inserts. Once you start wearing them out, it is (maybe) time for a better quality insert.

Like milling, most general values for feeds and speed don't work for your mill and will not work for your lathe. You have to figure out what works for you.

- Joined

- Dec 26, 2015

- Messages

- 2,079

I am of a completely different mindset from @Huub Buis. I have been doing lathe work for 20 years and have yet to grind my own HSS tooling. My shop is exclusively indexable tooling. While HSS tooling has it's place, and I don't disparage those who use it and grind their own, if you don't want to go down that rabbit hole, you don't have to to be successful.

Similarly, I also believe buying cheap insert tools is a bad idea, particularly for someone just getting started with insert tooling - when you don't get the results you were expecting, you have no idea if it is the tool, the insert, your setup, or your technique that's at fault, so why not eliminate some of these variables at the outset?

Since you have my book, take note of the "cost-benefit tradeoffs" discussion on page 6. And if you've gotten as far as page 11, you already know that I have recommended a basic set of three indexable tools to get started with. Also, starting on page 94, there is a thorough discussion on QCTP selection. Personally, I would recommend investing in the Dorian BXA, but other units are servicable. And take note of the differences in QCTP tool holder capacities and variances between brands noted on page 10 - so buy one type and try it before you invest in a boatload of tool holders. Feel free to DM me if you have additional questions.

Similarly, I also believe buying cheap insert tools is a bad idea, particularly for someone just getting started with insert tooling - when you don't get the results you were expecting, you have no idea if it is the tool, the insert, your setup, or your technique that's at fault, so why not eliminate some of these variables at the outset?

Since you have my book, take note of the "cost-benefit tradeoffs" discussion on page 6. And if you've gotten as far as page 11, you already know that I have recommended a basic set of three indexable tools to get started with. Also, starting on page 94, there is a thorough discussion on QCTP selection. Personally, I would recommend investing in the Dorian BXA, but other units are servicable. And take note of the differences in QCTP tool holder capacities and variances between brands noted on page 10 - so buy one type and try it before you invest in a boatload of tool holders. Feel free to DM me if you have additional questions.

- Joined

- Feb 23, 2016

- Messages

- 424

I am of a completely different mindset from @Huub Buis. I have been doing lathe work for 20 years and have yet to grind my own HSS tooling. My shop is exclusively indexable tooling. While HSS tooling has it's place, and I don't disparage those who use it and grind their own, if you don't want to go down that rabbit hole, you don't have to to be successful.

Similarly, I also believe buying cheap insert tools is a bad idea, particularly for someone just getting started with insert tooling - when you don't get the results you were expecting, you have no idea if it is the tool, the insert, your setup, or your technique that's at fault, so why not eliminate some of these variables at the outset?

Since you have my book, take note of the "cost-benefit tradeoffs" discussion on page 6. And if you've gotten as far as page 11, you already know that I have recommended a basic set of three indexable tools to get started with. Also, starting on page 94, there is a thorough discussion on QCTP selection. Personally, I would recommend investing in the Dorian BXA, but other units are servicable. And take note of the differences in QCTP tool holder capacities and variances between brands noted on page 10 - so buy one type and try it before you invest in a boatload of tool holders. Feel free to DM me if you have additional questions.

Yeah, I am 100% determined not to mess with grinding my own tools. I respect that there are different philosophies about this, as there are about most everything, including getting into tools: I heard about buying a small lathe then upgrade vs buying an old higher- grade US-made lathe etc. I am thankful for all the input.

I have parsed all these alternatives, and have considered their tradeoffs. Then I decided to buy new, Taiwanese, and a relatively larger size (the 1340) which will very likely be the last lathe I need; for tooling will go for quality from the outset, and inserts only.

Will upgrade the lathe immediately with the Clough ELS, and in the future, consider 3-phase (high likelihood) and perhaps CNC conversion (low likelihood).

- Joined

- Sep 1, 2023

- Messages

- 468

As you have the financial wherewithal to do what you're doing, I think you're taking a pretty sensible route.

I'm having a great, (if occasionally ever so slightly eye-rolling time; mostly at my own daftness) learning journey with my 7x14. I'm learning a lot about mechanical principles, some workaround techniques and particularly that I'm actually a fair bit less incompetent that I initially feared.

However, if I had been able to lay my hands on the funds to go the way you're going, I suspect I'd know a lot less about the ins and outs of Chinese mini-lathes and be further on in my learning about actual machining on a lathe and not be too concerned about my ignorance.

@davidpbest is absolutely spot on about the 'meta' of learning. Nothing is more frustrating than hitting a 'wall' and not knowing if your 'failures' (and whilst it's sickeningly cheesy to say so, failures are often an opportunity to learn and as hobbyists, we have the luxury of nobody's lives or livelihoods depending on our success ) are down to you needing more practice/more information on the one hand or your equipment not being up to scratch.

) are down to you needing more practice/more information on the one hand or your equipment not being up to scratch.

Keep posting updates, this thread has been really interesting to read.

I'm having a great, (if occasionally ever so slightly eye-rolling time; mostly at my own daftness) learning journey with my 7x14. I'm learning a lot about mechanical principles, some workaround techniques and particularly that I'm actually a fair bit less incompetent that I initially feared.

However, if I had been able to lay my hands on the funds to go the way you're going, I suspect I'd know a lot less about the ins and outs of Chinese mini-lathes and be further on in my learning about actual machining on a lathe and not be too concerned about my ignorance.

@davidpbest is absolutely spot on about the 'meta' of learning. Nothing is more frustrating than hitting a 'wall' and not knowing if your 'failures' (and whilst it's sickeningly cheesy to say so, failures are often an opportunity to learn and as hobbyists, we have the luxury of nobody's lives or livelihoods depending on our success

Keep posting updates, this thread has been really interesting to read.

- Joined

- Feb 23, 2016

- Messages

- 424

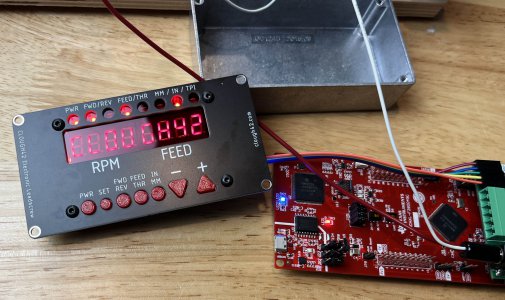

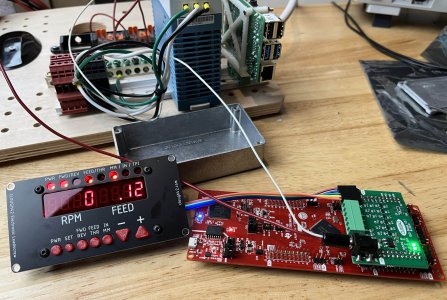

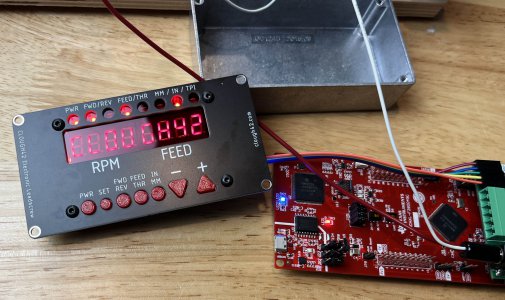

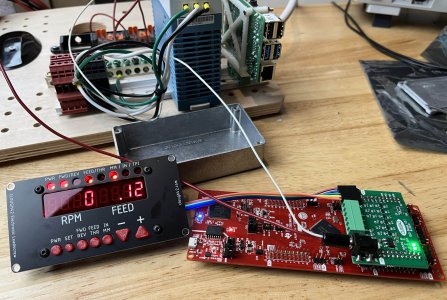

Clough42 ELS

While studying @davidpbest 's book on tooling I have put together the basic three tools (turning, facing, parting) in my shopping cart at MSC Direct. Still deciding on threading tools.

In the meantime, my order for the electronic lead screw has arrived, specifically the display with the power source as a kit from Clough, and the Texas Instruments board from Mouser. The power source board arrives unfinished, meaning the headers have to be soldered on. Thank God the tiny components are soldered on, otherwise I couldn't have done it.

Once I soldered those on, I turned to the TI Board. I was a bit apprehensive despite having watched James' video on the subject:

I do not have any experience with C/C++ programming or the IDEs and project management needed. Plus the current version of the Texas Instruments IDE is 12.x whereas he was working on 9.x (the debug probe support is different on 12.x and some comments in the video mentioned they could not make it work with v10). Next, I am using a Mac, while he was on Windows. So lots of things could have gone wrong, but actually the firmware compiled without any error (and only one warning) and it transfered to the controller without a hitch. The system booted up nicely. You can't tell in the photo below, but that is the splash screen that says "Clough42":

The buttons all work:

Next to the encoder and figuring out the motor connections and its power supply.

While studying @davidpbest 's book on tooling I have put together the basic three tools (turning, facing, parting) in my shopping cart at MSC Direct. Still deciding on threading tools.

In the meantime, my order for the electronic lead screw has arrived, specifically the display with the power source as a kit from Clough, and the Texas Instruments board from Mouser. The power source board arrives unfinished, meaning the headers have to be soldered on. Thank God the tiny components are soldered on, otherwise I couldn't have done it.

Once I soldered those on, I turned to the TI Board. I was a bit apprehensive despite having watched James' video on the subject:

I do not have any experience with C/C++ programming or the IDEs and project management needed. Plus the current version of the Texas Instruments IDE is 12.x whereas he was working on 9.x (the debug probe support is different on 12.x and some comments in the video mentioned they could not make it work with v10). Next, I am using a Mac, while he was on Windows. So lots of things could have gone wrong, but actually the firmware compiled without any error (and only one warning) and it transfered to the controller without a hitch. The system booted up nicely. You can't tell in the photo below, but that is the splash screen that says "Clough42":

The buttons all work:

Next to the encoder and figuring out the motor connections and its power supply.

Last edited:

- Joined

- Feb 23, 2016

- Messages

- 424

It has arrived!

Now to set it up. Will try to rent a pallet jack and an engine hoist.

What is the best solvent to use to clean off the cosmoline?

Sent from my iPhone using Tapatalk Pro

Last edited:

- Joined

- Oct 7, 2020

- Messages

- 2,113

WD40

- Joined

- Aug 2, 2020

- Messages

- 561

Ordinary mineral spirits.

It has arrived!

Now to set it up. Will try to rent a pallet jack and an engine hoist.

What is the best solvent to use to clean off the cosmoline?

Sent from my iPhone using Tapatalk Pro