-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dipping my toes into turning

- Thread starter koenbro

- Start date

- Joined

- Jul 6, 2022

- Messages

- 498

Yeah, I am 100% determined not to mess with grinding my own tools. I respect that there are different philosophies about this, as there are about most everything, including getting into tools: I heard about buying a small lathe then upgrade vs buying an old higher- grade US-made lathe etc. I am thankful for all the input.

I have parsed all these alternatives, and have considered their tradeoffs. Then I decided to buy new, Taiwanese, and a relatively larger size (the 1340) which will very likely be the last lathe I need; for tooling will go for quality from the outset, and inserts only.

Will upgrade the lathe immediately with the Clough ELS, and in the future, consider 3-phase (high likelihood) and perhaps CNC conversion (low likelihood).

I can’t tell an awful lot from the pictures you post of this lathe below, but the UK version of the standard 1340 lathe from Warco and the PM version have a built in gearbox for threading. What does the ELS give you above and beyond this? Or does your lathe not have the QCGB?

Sent from my iPhone using Tapatalk

- Joined

- Feb 23, 2016

- Messages

- 424

Yeah it has a threading gearbox but I believe one has to change gears for metric. Also would like to see RPMs.I can’t tell an awful lot from the pictures you post of this lathe below, but the UK version of the standard 1340 lathe from Warco and the PM version have a built in gearbox for threading. What does the ELS give you above and beyond this? Or does your lathe not have the QCGB?

Sent from my iPhone using Tapatalk

- Joined

- Feb 23, 2016

- Messages

- 424

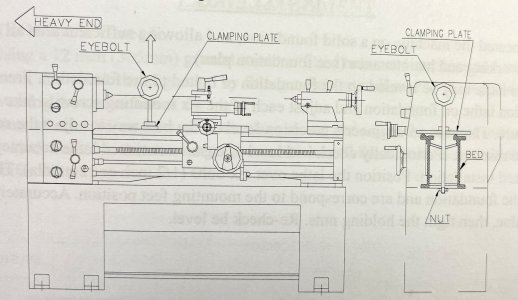

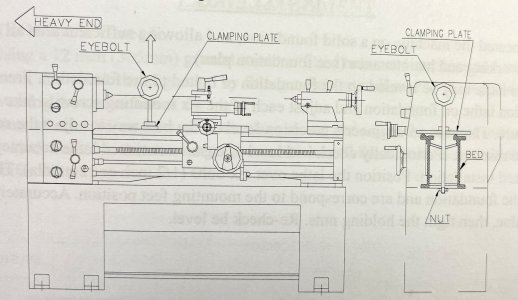

How To Lift

I can rent a pallet jack from Home Depot, but they don't rent engine hoists/lifts, so I might buy one from Harbor Freight. The question is how to lift the lathe once the base is assembled? The manual refers to a "bed clamping plate with an eyebolt"/ See this photo from the manual:

The lathe does not come with one, Eisen does not sell one on their website and could not find one elsewhere (one mention on the PM forum tells me this is a real item people have seen in the wild, though).

Can I make one myself? I suppose I could cut .25" plate on the plasma table and weld it together.

I do not want to chip the ways or otherwise damage the lathe. Would rather not put a strap around, lest I damage the screws. Any advice?

The bed has two large holes otherwise.

I can rent a pallet jack from Home Depot, but they don't rent engine hoists/lifts, so I might buy one from Harbor Freight. The question is how to lift the lathe once the base is assembled? The manual refers to a "bed clamping plate with an eyebolt"/ See this photo from the manual:

The lathe does not come with one, Eisen does not sell one on their website and could not find one elsewhere (one mention on the PM forum tells me this is a real item people have seen in the wild, though).

Can I make one myself? I suppose I could cut .25" plate on the plasma table and weld it together.

I do not want to chip the ways or otherwise damage the lathe. Would rather not put a strap around, lest I damage the screws. Any advice?

The bed has two large holes otherwise.

Last edited:

- Joined

- Oct 4, 2016

- Messages

- 7,021

Cargo sling webbing works also.

www.uscargocontrol.com

www.uscargocontrol.com

Nylon Lifting Slings | Nylon Slings, Lifting Straps & Web Slings

Our nylon lifting slings & straps are made in the USA from heavy duty webbing treated to improve abrasion resistance, keep moisture out, and reduce wear.

- Joined

- Jun 12, 2014

- Messages

- 4,811

You can do a D-ring with a plate on either side of the bed or a strap. Always try to counterbalance the headstock weight by moving the carriage and tailstock to the other end, and make SURE they are locked down. Always have two jack straps for tilt. You need at least a 2T engine hoist to stradle the cabinet and get the height. Laso consider a 2T gantry crane type, they often rent for $75/day work very well for full size lathes and mills.

www.hobby-machinist.com

www.hobby-machinist.com

New PM-1236T Lathe has arrived

It is hard to get better than 0.0005" on a set-true 5C because the collet specs. usually have a TIR range greater than that. But good enough, and in general it should repeat with 4-5 ten thousandths. Deflection of 0.0005" is about what one would expect, I had a 1340GT and that was about the...

www.hobby-machinist.com

www.hobby-machinist.com

- Joined

- Feb 23, 2016

- Messages

- 424

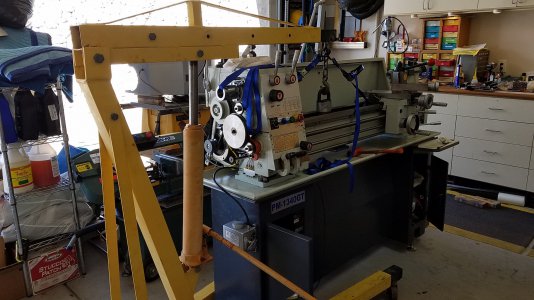

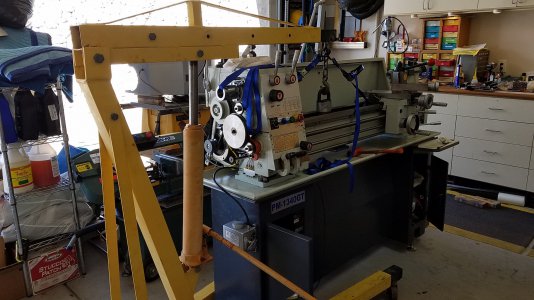

Ok I am now the owner of a 2-ton Harbor Freight engine hoist, whose first job was to remove from my pickup the rental pallet jack from Home Depot (I needed to reposition the pallet and rotate it 180 degrees), but then I moved the lathe in position. It was harder then expected, using one lifting strap for the weight, a second one for backup and two ratcheting straps for tilt/balance. That hook the hoist comes with seems like a poor solution, I used a shackle from my off-roading recovery kit.

I used a piece of steel under the bed and looped the yellow strap around it.

@mksj -- very impressed by the steel solution you showed!

Last edited:

- Joined

- Feb 23, 2016

- Messages

- 424

Where do you mount your DRO? For me the headstock would feel more natural but before drilling into it I’m going to use it to see the ergonomics. Now it’s mounted on some scrap melamine.

Sent from my iPhone using Tapatalk Pro