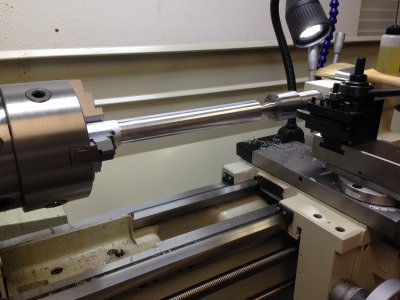

Contrats, my G0709 was delivered to my workplace last Thursday (4/23). I got it home Friday evening and put it in my tractor shop until I get everything cleaned up, adjusted, and the DRO installed, then I'll move it across the drive to my machine shop. Mine had a slight bit of damage, the chip guard was bent in about an inch from a blow to the back of the crate, I can straighten it with no problem. The bolt had come out of the bottom of the tailstock, and the tailstock had fell off the back of the bed. It snapped the coolant tube off on it's way down, and put a scratch in the chip guard, but that was the extent of it. I emailed Grizzly today for a replacement tube. I am already happy with the smoothness of the carriage, cross slide, and compound, I think I'll really like it. I am replacing an 11" x 36" Logan that was made in 1952, the year I was born. I already have a G0755 mill in my machine shop with a DRO, that I really like. I'm anxious to start making chips, but it will probably be a couple of weeks at least as a lot of other projects take precedence.