@paradox_pete Ditto for GMondshine's request. Particularly the pullys and belts used. If I understand, with hybrid servo Clough42 ended up going with I don't need a seperate servo box/controller. Sorry if I am using the wrong terminology. I only have basic electronic skills. Thanks Pete!

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Has anyone installed Clough42's electronic leadscrew on a PM machine?

- Thread starter Pcmaker

- Start date

- Joined

- Dec 7, 2022

- Messages

- 6

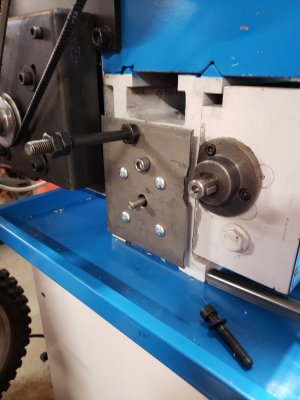

Hello Pete, I have a PM 1022 which should be nearly identical to your PM 1030 at least on this end of the lathe. Do you have the part numbers for the encoder and stepper motor you used in this installation? I am trying to put together a list of items I need to purchase to complete this conversion. I already purchased the two electronic components from James but that is all I have thus far. Thanks for any help.I recently finished installing one on my PM1030v. I used the integrated servo James did a review on a couple of months ago, primarily because it eliminated the need for a separate stepper driver. Because the PM has a separate feed drive from the leadscrew I'm using a slightly different approach to the gear reduction between the servo and the leadscrew. Like James I'm using a 3:1 gear reduction belt drive from the servo to the gearbox on the lathe. When threading I use the 2:1 position on the lathe gearbox (same as James) for an overall reduction of 6:1. However the power feed in the PM1030 effectively provides an additional 10:3 gear reduction in the saddle, which I felt was too much gear reduction, so I have mine programmed to be used with the gearbox in the 1:2 position providing an overall gear reduction of 5:1 in feed mode. I integrated everything except the servo power supply in the lathe itself. The servo is mounted inside the lathe bed casting (this was a tight fit), and the electronics are mounted in the electric enclosure on the back of the lathe. The encoder and servo mounts are 3d printed parts. The power supply is mounted to the bottom of the bench top the lathe sits on.

-Pete

A couple of pictures....View attachment 378143View attachment 378145

Timothy

- Joined

- Feb 7, 2021

- Messages

- 90

To be honest, you should really be looking at James' ELS Wiki. I used the exact same encoder and integrated servo linked in the "Stuff You'll need section"Hello Pete, I have a PM 1022 which should be nearly identical to your PM 1030 at least on this end of the lathe. Do you have the part numbers for the encoder and stepper motor you used in this installation? I am trying to put together a list of items I need to purchase to complete this conversion. I already purchased the two electronic components from James but that is all I have thus far. Thanks for any help.

Timothy

I think used 20 and 60 tooth pulleys on the servo and leadscrew, but not absolutely certain. I tried to check the Ebay purchase history, but it doesn't show specifically which tooth count pulleys I purchased. I also don't know just what belt length I used, I got the pulley's first and then just measured the length needed... That's probably the best approach regardless, just in case there are slight variations in machines. I seem to recall having to bore out one side of the big pulley a little to get it far enough onto the leadscrew shaft to line up with the servo pulley.

I'm afraid that it is all such a tight fit that getting it apart to measure is too much of a nuisance for me to be willing to take it apart and check what I used. Also, I'm making some christmas gifts on the lathe, so don't want to interrupt that. Sorry.

I will say I REALLY like the ELS. I almost never cut threads with a die anymore. I usually cut female threads smaller than 1/2 inch with a tap, and single point the male thread to a close fit. It's just so easy to set up to single point the threads. Also nice for oddball threads. I just cut a ~7/8"-48 (both the female and male thread) for a project and it was so easy. Especially using the tool upside down, lathe in reverse and thread away from the chuck method Joe Pie teaches on his Youtube....

I hope that helps.

-Pete

First test. I need to get into the driver to change the settings and then I need to cut that encoder gears once thay gets here..

Motor mount is done and it fits perfectly. I can get the motor in and setup in 5 minutes so I'm really happy with that..

Motor mount is done and it fits perfectly. I can get the motor in and setup in 5 minutes so I'm really happy with that..