D

Dr Stan

Forum Guest

Register Today

Here's my Logan 14 X 30 as it sat at the dealer.

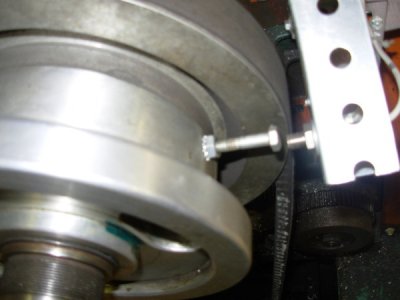

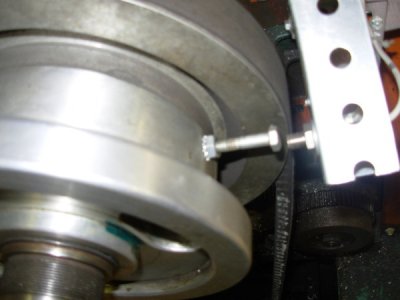

Since then I've added a DRO and a tachometer & prox sensor so I can set my RPMs as needed. The door on cabinet under the tailstock end opens from the end of the machine instead of the front. The dealer bought it at an estate sale of a machinist who had a one man shop and purchased it new sometime in the early 70's. Excellent condition and came with a Buck six jaw through set. I added a 12" and a 8" four jaw, a 6" 3 jaw that also mounts to my rotary table, and the collet chuck I already owned. Bought a Chinese steady rest off EBay and made a new base for it to fit the Logan. It has a 5hp 3 phase motor so I went with a rotary phase converter. Glad I did as I can run my surface grinder off the same RPC.

Since then I've added a DRO and a tachometer & prox sensor so I can set my RPMs as needed. The door on cabinet under the tailstock end opens from the end of the machine instead of the front. The dealer bought it at an estate sale of a machinist who had a one man shop and purchased it new sometime in the early 70's. Excellent condition and came with a Buck six jaw through set. I added a 12" and a 8" four jaw, a 6" 3 jaw that also mounts to my rotary table, and the collet chuck I already owned. Bought a Chinese steady rest off EBay and made a new base for it to fit the Logan. It has a 5hp 3 phase motor so I went with a rotary phase converter. Glad I did as I can run my surface grinder off the same RPC.