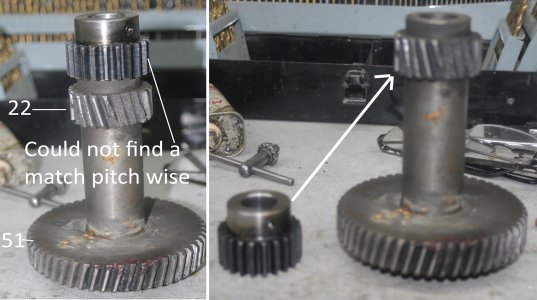

As in title looking for a new or good used backgear for my model shop lathe.

Sadly working on a bad day I let the 4 jaw chuck during a complex job hit the carriage, this took out a number of teeth on the small end of the backgear which I using for the low speed of a off center part.

Rich

Sadly working on a bad day I let the 4 jaw chuck during a complex job hit the carriage, this took out a number of teeth on the small end of the backgear which I using for the low speed of a off center part.

Rich