Hello Michael

Compliments of the Season and thanks for posting Your progress with Your beloved Cromwell.

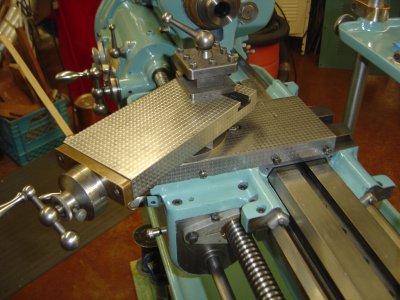

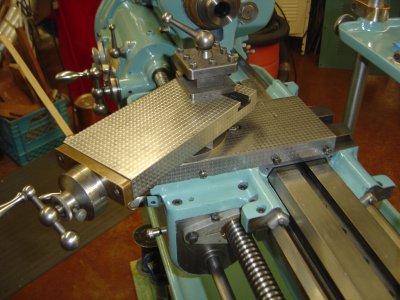

Your work is coming out nice, especially the Jewelling. We use quite a bit of this on our knives with CRATEX STICKS only on a Drill Press. However, Your method of utilising graded lapping compound with a wooden dowel on a milling machine is quite a novel approach to a similar task, which we would also like to experiment with.

Regrettably I picked Your progress a bit late, but then it's never too late, 'cos we have a myriad of questions U might be able to assist us with on whether we can or should attempt to tackle a similar project.

U see we had recently acquired a COLCHESTER CHIPMASTER which is in a pathetically butchered condition and we can't decide whether we should sell it or keep the machine and tackle a complete overhaul, like U and most of the knowledgeable, experienced Guys do here. Pics etc., are in that section of the Forum here.

At the outset, allow me to be candid and say that we have zero knowledge when it comes to the innards of these Lathes.

If we open say the Apron/Saddle, heaven help us if we will be able to put back all the Gears etc. !!!

This machine, being rather noisy, may have VARIATOR issues, a scrape on the BED requires removal, the MATRIX CLUTCH requires adjustment, excessive Back play on the Handwheels needs correction etc., etc. Being some 33 years old it would obviously need serious attention.

To begin with, without sounding impetuous or impertinent, what is Your level of expertise with these machines ??? Remember, unlike U, we are rookies at most.

Is this Your first re-furbishing attempt ???

If U were to advise one to tackle a similar project, where would U recommend they start ???

We understand taking pics and numbering will greatly assist in maintaining a proper sequence of technical part configuration.

However, how would one cope should one get totally stuck with putting parts back in the right order and sequence ???

Will the machine Manual adequately suffice for this ???

Surprisingly we note that U did use a paint brush for most of the painting, except for what we can see, the Motor ???

As moving our heavy ( +500 lbs ) Lathe would be a serious challenge, Your method of using a Brush would circumvent that impasse.

And your work is beautiful, to say the least !!!

We have had other well-intentioned well wishers with an exactly similar Make and Model on the Forum here highly recommend we keep the machine and sort the few problematic issues.

Regrettably, we could not make up our minds.

As an impartial observer, we would like to pose the same question to U.

Should we or should'nt we commence serious re-furbishing, knowing our level of total technical ignorance ???

Your esteemed advices would be immensely appreciated.

Thanks in advance

Regards

aRM