- Joined

- Sep 27, 2014

- Messages

- 3,123

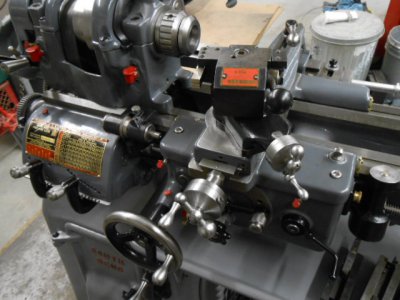

HI all, got the apron done except, waiting on half nut lever/cam from joe. The saddle, cross slide ,taper attach, paint is drying.Got new cross slide / compound bronze nuts . Ted is sending reverse tumbler gear stud after holidays. Glued new 8 rib serpentine belt with flexible super glue, filled spindle cone pulley and back gear shaft w/ super lube, ran head stock, lower drive, motor for a while, all ran smooth and quiet, large spindle bearing and inside spindle seemed to get a little warm after 15 min tho.

Had to step it up with getting this lathe done as i'll be having shoulder surgery mid jan . :bitingnails:

Thanks to you all for your help, suggestions, advice. I'll post final pics and mach performance results after the first when all parts are in and on.

Do the felt kits/ book normally come with extra felt , I'm sure i got what the book said put in but there is extra felt?.

O yea anyone use machine leveling feet "amazon", with or without rubber pads, as i will not be able to bolt lathe down to floor and thought they might be good ? . I'll probably make 1/4" plates with 1/2" hole to match footprint of castings for them.

Thanks again and y'all have a great holiday

Derrick

Had to step it up with getting this lathe done as i'll be having shoulder surgery mid jan . :bitingnails:

Thanks to you all for your help, suggestions, advice. I'll post final pics and mach performance results after the first when all parts are in and on.

Do the felt kits/ book normally come with extra felt , I'm sure i got what the book said put in but there is extra felt?.

O yea anyone use machine leveling feet "amazon", with or without rubber pads, as i will not be able to bolt lathe down to floor and thought they might be good ? . I'll probably make 1/4" plates with 1/2" hole to match footprint of castings for them.

Thanks again and y'all have a great holiday

Derrick