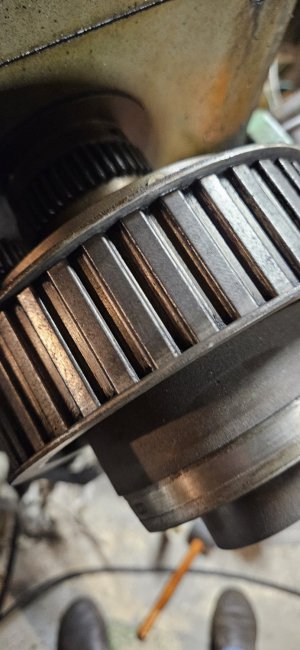

After dropping motor bracket and pulling the motor forward. I used a balljoint fork, 1/4" , and 1/2" shim plates to remove rear motor pulley. You can see why with all the burrs from being spun on the motor shaft.

I have no idea why someone would even mess with removing or trying to remove for any other than a motor swap or replacing pulley assembly.

Oviously some prior thought they should and didnt reassemble properly, which biffed the bearings and drive system.

It appears that it was mounted almost an inch from where it originally resided on the shaft.

So now we are starting to get a little costly. I have a replacement used pulley assembly in the works and thinking its probably a good idea to buy a new invertor duty div.1 class 2 motor. The vertical adjustment on the motor mount will help with a 145T frame swap and adapter plate to save a little bread. I previously was looking at and purchased a similar motor for my Enco 110-2034. One difference is that I'll stick with cast iron over aluminum and opt for WEG or similar. I've previously bought and liked Techtop for lighter applications. With a reeves drive, i'd rather go a bit heavier. I've used WEG for a lot of hydraulic applications and they stand up well.

We will see. Regardless, I still plan on cleaning up shaft, refurbing, and replacing bearings in the original.

Also tossing the idea around of just replacing the plastic bushing, removing the coating, and going with a bronze bushing. The question is SAE 841 or SAE 660? That would be around $40 instead of $350 for a

used pulley assembly replacement.

And then there is modifying the drive and just using the motor, vfd, and timing pulleys.