- Joined

- Apr 23, 2018

- Messages

- 6,830

I'm a bottom line up front kinda guy, so I waited to start this thread until I had the following pictures to show:

Now that that's out of the way...

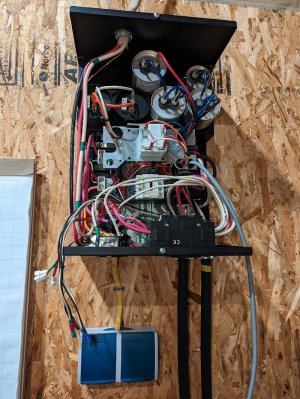

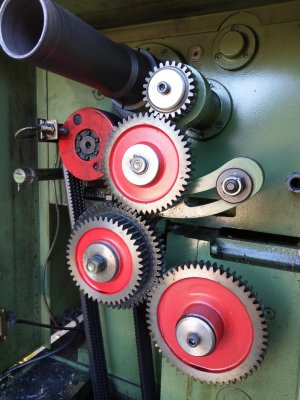

This thread is a long time coming, because I started this project in June of 2022. Ever since I bought my first lathe (1937 Atlas H-54), I have been wont for more lathe. Not just power, it was obvious that I wanted mass and rigidity more than anything else. Another thing that needed an upgrade was change gears- it was a pain to deal with for each and every feed and pitch. I new I would not be happy with anything under 14", and I wanted a machine that represented a capital investment at some point in its life- so not a hobby machine. I decided on a few other features, like a direct mount spindle and removable gap. Then there's country of origin... China is a hard pass, and Taiwan was off my list except for the Mori-Seiki clones, those are great lathes. USA would be fine, but for two problems- First, nearly all American iron is worn loose and swayed like the town bicycle, and that's a hard fact to get around. Second, old American iron seems deficient in the 127 tooth gear category. What I mean by that is no metric threads, a total deal breaker in this day and age. So American iron is a maybe, with Clausings and a couple other rarities that do run metric feeds. That leaves Europe! The land of Vost, Sagiano, Ferm, Frajoth, and other amazing machines. Then there's the other America, specifically Brazil. I always liked Nardini lathes. 256 threads and feeds without changing a single gear! If you do need module threads, you have to open the cabinet and slide a gear into position (darn). Nardini was a German co-operation with big capital in Brazil, so the components are all EU sourced and mostly German (bearings!). Nardini also makes Romi and Bridgeport lathes, while not as fancy in the drive system, they were high on the search list.

I also wanted a machine in decent condition. Someone else can have the payments while it's new, but whatever machine I end up with needs to be ready for precision work. That's where the rub is, any useful capital life remaining in these machines is included in the price tag. At this point, my wife and I decided to sell our house in Germany. It was a tough decision for me, as I love living there, but the state of politics is always changing. Agreeing we were entering the dark ages, I reluctantly sold out. It sure helped with this project, though!

Cash in hand and goals listed, I searched surplus record and machinio. They are aggregator sites. You find a listing, then pursue the seller. I called on a couple of machines, but this one in Cinci seemed right. It was built in 2002, so it's even newer than my mill.

The original listing is still up (marked sold):

www.mohawkmachinery.com

www.mohawkmachinery.com

Here are the listing pics that I based all of my decision on:

Not bad, just a little dirty. I wasn't sure how much the equipment dealers were willing to negotiate, so I tried. The sales rep said they usually don't have much wiggle room, but gave me a $950 break on the machine. I paid $8000 for the lathe, and contracted freight from Cincinnati to Seattle for $2400. I unloaded it with a long reach lift that cost me $1000 because it's all that was available at all the places I called between here and Tacoma. That part sucked, but I got the lathe unloaded and in my shop within an hour.

Time to start uploading pics. I have plenty!

Now that that's out of the way...

This thread is a long time coming, because I started this project in June of 2022. Ever since I bought my first lathe (1937 Atlas H-54), I have been wont for more lathe. Not just power, it was obvious that I wanted mass and rigidity more than anything else. Another thing that needed an upgrade was change gears- it was a pain to deal with for each and every feed and pitch. I new I would not be happy with anything under 14", and I wanted a machine that represented a capital investment at some point in its life- so not a hobby machine. I decided on a few other features, like a direct mount spindle and removable gap. Then there's country of origin... China is a hard pass, and Taiwan was off my list except for the Mori-Seiki clones, those are great lathes. USA would be fine, but for two problems- First, nearly all American iron is worn loose and swayed like the town bicycle, and that's a hard fact to get around. Second, old American iron seems deficient in the 127 tooth gear category. What I mean by that is no metric threads, a total deal breaker in this day and age. So American iron is a maybe, with Clausings and a couple other rarities that do run metric feeds. That leaves Europe! The land of Vost, Sagiano, Ferm, Frajoth, and other amazing machines. Then there's the other America, specifically Brazil. I always liked Nardini lathes. 256 threads and feeds without changing a single gear! If you do need module threads, you have to open the cabinet and slide a gear into position (darn). Nardini was a German co-operation with big capital in Brazil, so the components are all EU sourced and mostly German (bearings!). Nardini also makes Romi and Bridgeport lathes, while not as fancy in the drive system, they were high on the search list.

I also wanted a machine in decent condition. Someone else can have the payments while it's new, but whatever machine I end up with needs to be ready for precision work. That's where the rub is, any useful capital life remaining in these machines is included in the price tag. At this point, my wife and I decided to sell our house in Germany. It was a tough decision for me, as I love living there, but the state of politics is always changing. Agreeing we were entering the dark ages, I reluctantly sold out. It sure helped with this project, though!

Cash in hand and goals listed, I searched surplus record and machinio. They are aggregator sites. You find a listing, then pursue the seller. I called on a couple of machines, but this one in Cinci seemed right. It was built in 2002, so it's even newer than my mill.

The original listing is still up (marked sold):

Used 17"/24" X 60" NARDINI "NODUS ND1760" GAP-TYPE ENGINE LATHE for Sale at Mohawk Machinery

17"/24" X 60" NARDINI "NODUS" GAP-TYPE ENGINE LATHE SERIAL NO D3JDP057, TYPE ND1760, SERIES NODUS EQUIPPED WITH: 12" 4-JAW CHUCK - 10" 3-JAW CHUCK INDUCTION HARDENED & GROUND BED WAYS SMALL BOX OF TOOLING W/5C COLLET ATTACHMENT & COLLETS STEADY RE...

Here are the listing pics that I based all of my decision on:

Not bad, just a little dirty. I wasn't sure how much the equipment dealers were willing to negotiate, so I tried. The sales rep said they usually don't have much wiggle room, but gave me a $950 break on the machine. I paid $8000 for the lathe, and contracted freight from Cincinnati to Seattle for $2400. I unloaded it with a long reach lift that cost me $1000 because it's all that was available at all the places I called between here and Tacoma. That part sucked, but I got the lathe unloaded and in my shop within an hour.

Time to start uploading pics. I have plenty!

That's a great looking lathe pontiac .

That's a great looking lathe pontiac .