- Joined

- Apr 23, 2018

- Messages

- 6,532

Sounds good, I'll clean you out if you're not planning to use them.

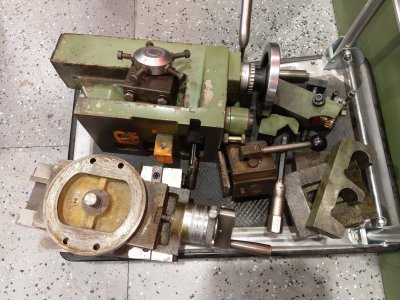

See, I thought you sold off those insert holders- I remember this from... uh, somewhere on this site. Yeah, PM me your price.Quick pic . Used them on my 17" Leblond which is gone . Have a Dorian BXA on the 14" Republic , so all these can go to make room . Off to work soon .

FWIW . We had a 20" Nardini down at the paper plant along with a 17" Colchester . The Nardini never got used and was in PERFECT condition . Don't know where it went when they closed the doors .

Love the names! Just hope neither detonates in the shop!I'll skip ahead a bit, because right at this point my big RPC arrived!

You may think that by having it on a dolly and in my driveway was good enough... This big ol' pig kicked my butt up the steps and across the yard.

View attachment 444179

The WEG motor on the Nardini has a 5 hp wind and an 8 hp wind. I had to buy a 20 hp rotary power converter to start that motor, apparently the Brazilian AC motors have high inductance. That means #6 wire and an 80-amp breaker.

View attachment 444178

Everything done up nice:

View attachment 444177View attachment 444175

I haven't been able to get away from EU appliances. I'll have to wait for that Bosch and Karcher stuff to wear out. Might take a while, so I'll add some 15 amp Schucko outlets (overdriven at 60 hz, but the motors don't care). This configuration is legally NEC exempt if you follow the wires.

View attachment 444176

I installed interphase volt/amp meters. They have a fast enough response rate to be useful. I also gave the 20 hp RPC an appropriate name tag:

View attachment 444174

And provided my 5 hp RPC with a similar name tag while I was at it!View attachment 444173: