- Joined

- Mar 10, 2015

- Messages

- 309

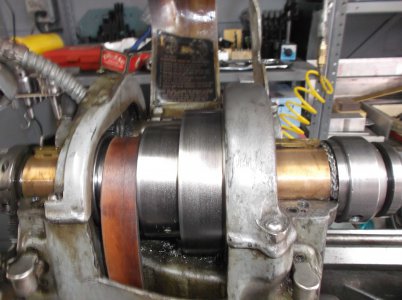

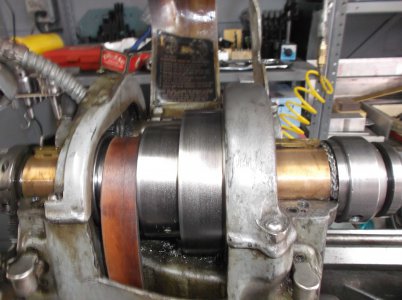

Been busy as hec at work only spent a little time in garage however turned out a few small lathe projects that I needed to get other machines up and running .. all I hav to say is this lathe is top shelf all I attempt to do the lathe does what its supposed to do .. Btw after I dialed her in can not find anything to fix .. Adjusted the brass bearing shims on spindle no need to buy a new spindle .Did a full head bearing adjustment less than .0002 TIR now .

, the lathe is smooth very ez to work on ... Its been a dream to finially have a functional lathe in my home .One happy camper thanks so much guys

, the lathe is smooth very ez to work on ... Its been a dream to finially have a functional lathe in my home .One happy camper thanks so much guys