- Joined

- Oct 14, 2014

- Messages

- 2,106

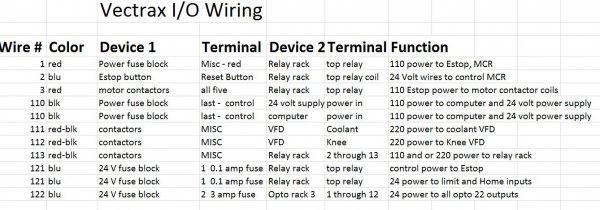

I've had a really nice Vectrac CNC knee mill with a Fanuc 0M control for quite some time. Great machine, but the old control is kludgy and impossible to maintain. Time to upgrade it.

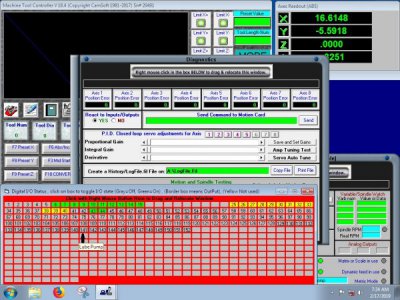

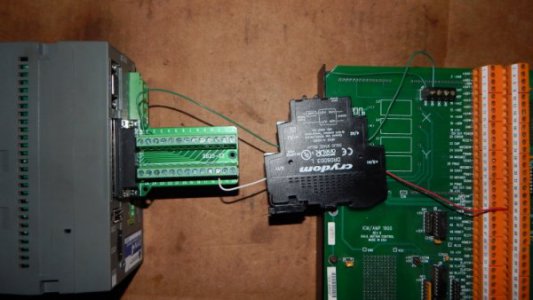

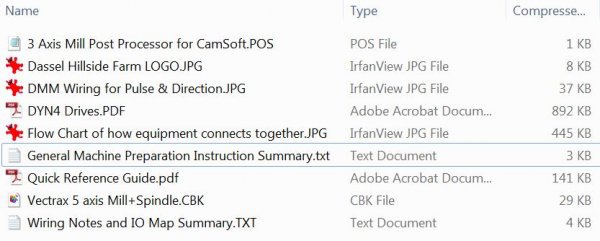

This will be my fifth machine refit to Camsoft controls. My goal is to make this one the best yet. The real strength of the Camsoft control is open sourcing of hardware and the ability to fully configure virtually an unlimited amount of I/O. (I have heard it said the biggest strength of Camsoft is everything is configurable. And the biggest weakness is everything is configurable) Camsoft is NOT a control that a person without a lot of machine control refit experience should attempt.

The plan will be to first get the machine running with a default control setup, then add a great many upgrades one at a time. The first and most important one will be a complete operator panel like seen on professional machines. This is the biggest difference between a hobby grade control and a pro control. Anther will be encoder feedback on the spindle to allow features like rigid tapping. A fourth axis will be added. This is a knee mill, a feature will be added to use the knee to do all the tool length offsets. This concept has already been accomplished on my Excello knee mill and really eliminates the big weakness of a knee mill - too small a Z travel. Got a few other things planned.

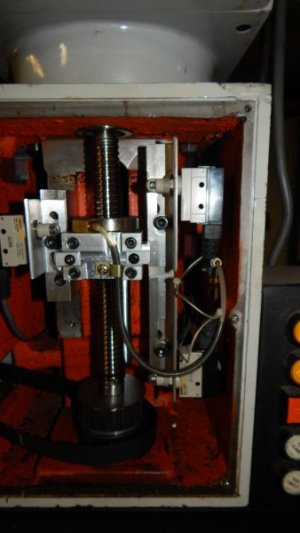

OK, here's before pics

This will be my fifth machine refit to Camsoft controls. My goal is to make this one the best yet. The real strength of the Camsoft control is open sourcing of hardware and the ability to fully configure virtually an unlimited amount of I/O. (I have heard it said the biggest strength of Camsoft is everything is configurable. And the biggest weakness is everything is configurable) Camsoft is NOT a control that a person without a lot of machine control refit experience should attempt.

The plan will be to first get the machine running with a default control setup, then add a great many upgrades one at a time. The first and most important one will be a complete operator panel like seen on professional machines. This is the biggest difference between a hobby grade control and a pro control. Anther will be encoder feedback on the spindle to allow features like rigid tapping. A fourth axis will be added. This is a knee mill, a feature will be added to use the knee to do all the tool length offsets. This concept has already been accomplished on my Excello knee mill and really eliminates the big weakness of a knee mill - too small a Z travel. Got a few other things planned.

OK, here's before pics

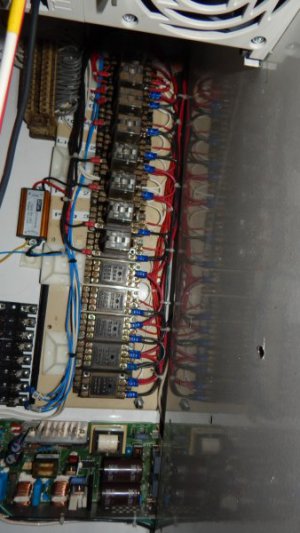

I have used the door and the cabinet sides when needed. It seems there is never enough panel real estate.

I have used the door and the cabinet sides when needed. It seems there is never enough panel real estate.