I haven't kept up this thread. Sorry, life gets in the way sometimes.

I had an ABSOLUTELY AWFUL time getting the servos installed and running correctly. Would have given up on the whole project without the assisstance of Jim Dawson. I will bet he is tired of my constant requests.

The issue was run aways. NOT good with big powerful servos. Had more than one problem so fixing one thing didn't help. I'd put it back then try the other, so that trial did not work either. Just for a quick summary:

All the DMM servos want to run what I call backward. When finished, every axis has either reversed encoder or reversed axis direction in the Galil software setup.

The used Galil ICM was defective on the axis I selected to try first. had to replace it. Shopping for parts on eBay does have its disadvantages.

I installed an update to the Galil card and could not get it to respond after the update, so i went to a very old card. Never did get this one to run. luckily, another one came up on eBay. ( I sent the first card to Jim and he could find nothing wrong - then it worked for me when returned) The machine is still running with card number three.

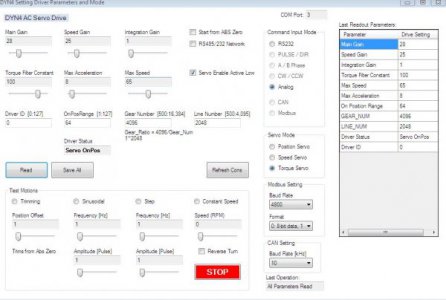

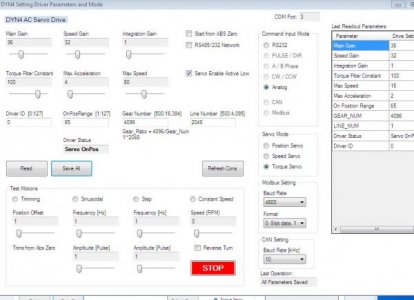

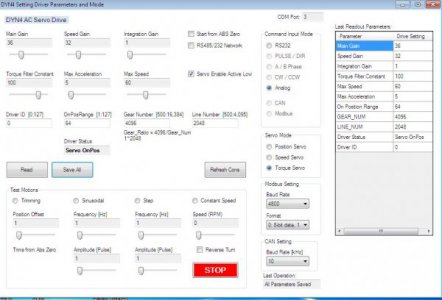

There is a parameter titled max speed. I had set this to a low value for testing. The title of this is extremely poor, it is actually the center of the voltage dead band for servo drift. A value of 65 is for 0 volts.

Biggest issue was with my misunderstanding of how Galil enable/disable should work. I thought is was a 5 volt output. it is acutally an open collector. Wasted a huge amount of time here. I promise to never make this particular mistake again. For DMM servos, connect the sevo enable input though a 2K resistor to the Galil enable output if using external 24 volt to power the servo's enable input. Then remove the RP1 resistor pack on the ICM. this results in backward function. So exchange the 7406 IC for a 7407.

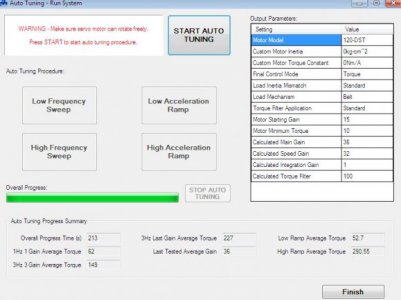

With all this finally resolved, the servos were tuned first under DMM. then again with Galil WSDK.

All the limit switches and home swithes were connected and debugged. An input from the Estop was connected to the galil card. outputs to the spindle knee and coolant were connected and debugged.

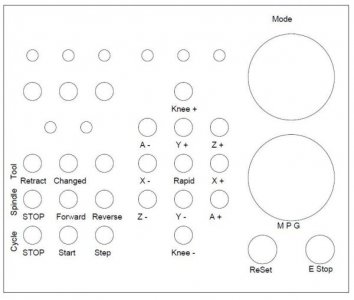

Camsoft was kind enough to provide a basic .cbk for this machine. A couple days making minor program edits to this .cbk has the machine up and running WOOHOO!

The machine could certainly be run as is. A great many stop at this point and go to work. But that's not the final goal for this machine. When complete the control will be better than even the newest commercial controls. I can say that because it will work exactly as I want it to.

Screen shots of the DMM servo setups are attached, mostly as a personal backup.