- Joined

- Jun 17, 2012

- Messages

- 2,220

What I can't figure out is how you'd rotate the axis of the feed handle so that both feed handles are parallel to each other. The gears (feed handles) need to be on the same plane unless you use a 90 degree gear box.

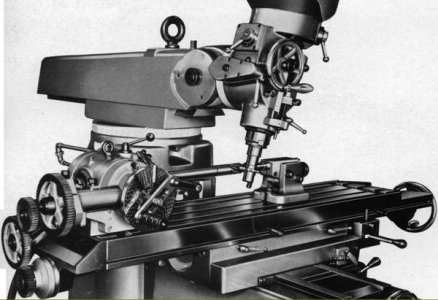

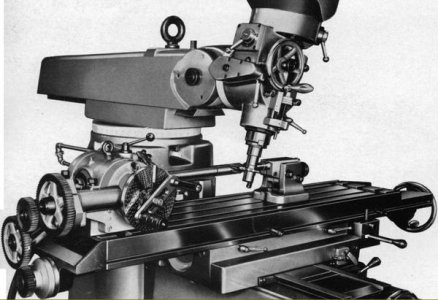

This is the one I have: http://www.grizzly.com/products/H7527

It was the best deal going for all the features, when I bought it, Might still be.

This is the one I have: http://www.grizzly.com/products/H7527

It was the best deal going for all the features, when I bought it, Might still be.

Last edited: