- Joined

- Dec 18, 2019

- Messages

- 6,480

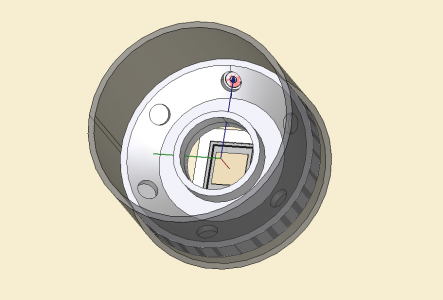

My first attempts at dealing with the lead were interesting. A far eastern copy of an xacto knife is almost, but not quite capable of cutting 1/16" lead. I had to resort to tin snips. I cut out a somewhat square piece almost 3" x 3". I traced out the center hole. Since my cutting did not quite go as expected, I decided to make a punch and die out of steel to cut out the center hole. I used a piece of 12L14 steel 3/4" diameter for the punch and bored a hole in a 2" disk of 1018 steel. My idea is to use the punch and die to cut out the center, using an arbor press. The gap between the punch and die are currently at about 0.0005". Was pretty happy to hit that. I'll try cutting around the edges to get it roughly circular. Might sandwich the lead between some big washers and turn the edge circular. At 1/16" thick, this lead is a bit stiffer than I expected. Tin snips work fine to cut the lead. My plastic die idea might not work. An aluminum or steel die might.

Think I made the steel die OD too small. Going to be tough to align on the arbor press. Might make a steel plate with a recess in it to locate the die and clamp the plate to the press. If I turn the top of the punch to 12mm, it will fit in the ram. Then I lower the ram, line up the plate and clamp it while the ram is down. Raise the ram, insert lead, then punch out the center. That's the plan... Got to work on it tomorrow.

Once the hole is punched, I will make a sandwich of a steel plate, the left red piece, the lead washer, and the right red piece. Then I will put the assembly on the arbor press and see what gives under pressure. I'm hoping it is the lead!

Think I made the steel die OD too small. Going to be tough to align on the arbor press. Might make a steel plate with a recess in it to locate the die and clamp the plate to the press. If I turn the top of the punch to 12mm, it will fit in the ram. Then I lower the ram, line up the plate and clamp it while the ram is down. Raise the ram, insert lead, then punch out the center. That's the plan... Got to work on it tomorrow.

Once the hole is punched, I will make a sandwich of a steel plate, the left red piece, the lead washer, and the right red piece. Then I will put the assembly on the arbor press and see what gives under pressure. I'm hoping it is the lead!