- Joined

- Jul 28, 2017

- Messages

- 2,390

I bought some 1uf plastic SMT's for a future from-the-ground-up detector board. The plastic caps are substantially larger than 1206's.

X7R and X5R ceramics are highly microphonic, particularly if they have a voltage across them. They are real similar in composition to real-deal piezoelectric devices. They also have higher leakage than polymer caps. There are reasons that it's a bad idea to put high-K ceramic capacitors in the signal path of audio amplifiers.

On a different subject, I have a couple of XRF spectrum I want to share. The first is for 1018 HRS, and the second is for aluminum. I'm _finally_ seeing a peak I believe may actually represent iron! But there also is a pretty strong peak from something else. That peak looks pretty much like the aluminum-only sample.

I think that high aluminum background is secondary xray fluorescence coming from my aluminum "focusing ring", perhaps generated by 6Kev xrays from the steel sample itself (!). I may have shot myself in the foot there, so you folks going with a plastic 3D printed focusing ring will likely get much better results right out of the chute.

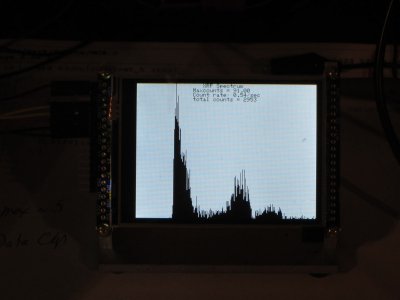

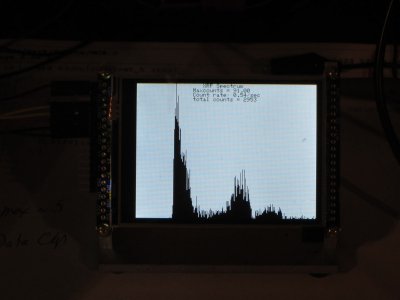

Iron + "X" (the iron is the peak on the far right):

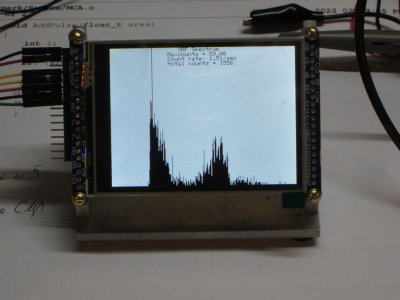

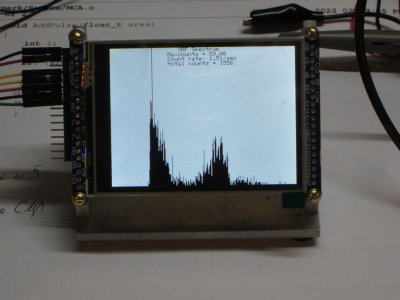

Aluminum + a little bit of "Y":

As you can see, the "X" looks a lot like aluminum and the "Y" looks like it could be iron, possibly coming from my little source disks -- or perhaps fastener hardware in my enclosure. I will try strategically placing some lead shielding here and there to see if I can get rid of the extraneous iron peak.

Right now I'm reluctant to scavenge my sources, preferring to keep the current setup for comparison purposes. So I just ordered 8 more sources from Ali Express, too. They are selling them for a lot less than Ebay right now. The sources should arrive the first week of March. This isn't too bad because I want to spend some time on the driver code for my 1MSPS ADC. It will be interesting to see how many "noise bits" my board design has.

X7R and X5R ceramics are highly microphonic, particularly if they have a voltage across them. They are real similar in composition to real-deal piezoelectric devices. They also have higher leakage than polymer caps. There are reasons that it's a bad idea to put high-K ceramic capacitors in the signal path of audio amplifiers.

On a different subject, I have a couple of XRF spectrum I want to share. The first is for 1018 HRS, and the second is for aluminum. I'm _finally_ seeing a peak I believe may actually represent iron! But there also is a pretty strong peak from something else. That peak looks pretty much like the aluminum-only sample.

I think that high aluminum background is secondary xray fluorescence coming from my aluminum "focusing ring", perhaps generated by 6Kev xrays from the steel sample itself (!). I may have shot myself in the foot there, so you folks going with a plastic 3D printed focusing ring will likely get much better results right out of the chute.

Iron + "X" (the iron is the peak on the far right):

Aluminum + a little bit of "Y":

As you can see, the "X" looks a lot like aluminum and the "Y" looks like it could be iron, possibly coming from my little source disks -- or perhaps fastener hardware in my enclosure. I will try strategically placing some lead shielding here and there to see if I can get rid of the extraneous iron peak.

Right now I'm reluctant to scavenge my sources, preferring to keep the current setup for comparison purposes. So I just ordered 8 more sources from Ali Express, too. They are selling them for a lot less than Ebay right now. The sources should arrive the first week of March. This isn't too bad because I want to spend some time on the driver code for my 1MSPS ADC. It will be interesting to see how many "noise bits" my board design has.