A couple of small updates...

I got started on cleaning a few small patches to see how bad things are, and I was surprised: it's not bad under there! Everything that's semi-brighter in the following pictures was spruced up with a paper towel soaked in a bit of Kroil; I think that some degreaser, microfiber cloths and some soft brass wool in selected areas would do a really nice job.

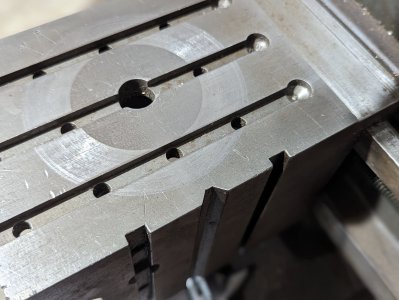

Pictured: The original milled surface is still visible outside of the wear range of the...uh...the whatever wears on this area.

View attachment 445554

Pictured: So, this may just be black paint, judging from the knocked-off spots on the front of the guard...but the knob looks pretty good!

View attachment 445555

Pictured: Turns out that it's Rockwell and/or battleship grey, underneath the grime.

View attachment 445556

Pictured: Vise surfaces aren't that bad, but there's some wear...but not much wear, considering.

View attachment 445557

Pictured: Damn. I didn't think the engravings would be this clear. That's a win.

View attachment 445558

I kind of knew that this thing was in decent shape, but I'm actually pretty impressed with just how clean it is; sure, it's caked with shop-grime on basically every surface - the horizontal ones are the worst, but the verticals aren't far behind - but that stuff will probably clean off pretty well. I may just set the entire thing in a large tub and start washing it down with...well, something. I don't really want to take a hose to it because that seems like nightmare fuel, so I may just take a bit of light-duty degreaser to it and see where we get. I've never seen Kroil cut paint before, but it cuts through everything else so I don't want to risk it here...and the more I look at this little thing, the more I don't want to restore it. It's somehow survived for somewhere around 80 years almost entirely intact, so I feel like I shouldn't deprive it of that achievement; making it showroom-perfect would...reduce it? Is that the phase I'm looking for? Regardless, it's a promising start and I think that a day of intensive cleaning will yield some pleasant results.

Also, I found a spare plug...so, this happened:

View attachment 445559

That motor doesn't just run, it

purrs. Instant, fast start, and it's damned smooth and quiet for its age...and that with basically no oil in the bearings in however-long. I was planning on oiling it and letting it move around a bit, but somehow I managed to relocate myself by 3,000 miles and not bring a single oiler with me...so I'll have to fix that before I let it do much more. I'll also need some fresh belts and the motor section bolted into place, but that's all an easy fix.

Stay tuned.