POTD was making some stainless steel blades for our cordless weed whacker. We have a Ryobi 40V unit which works pretty well. I'm not a big fan of the line reel which does a great job wrapping long weeds around the axle. Ours came with a plastic blade head also which works well on the taller stuff, but not the thicker stuff.

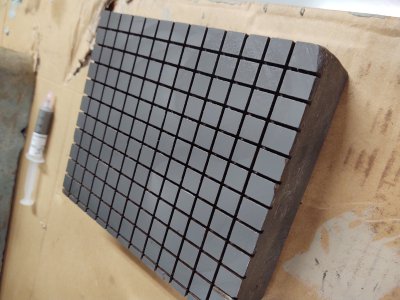

I like the design for convenient blade replacement. Bayonet mount head with snap-on blades. However, the plastic doesn't fair well against stones and thicker weeds.

View attachment 448676

View attachment 448677

View attachment 448678

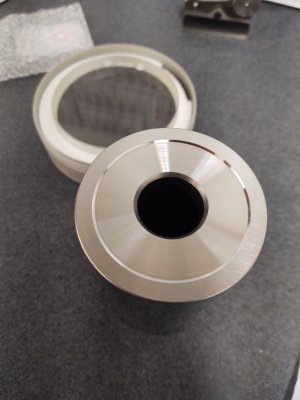

I grabbed some 0.036" stainless and Dykem'd a couple of holes to slip the blades over a set of the plastic ones. Did the rough hole on the Bridgeport (alas, no photos). Then over to the Oliver die filer for a tight fit. I was a little worried about the stainless separating from the plastic blade and launching it into my foot, so went with a slotted hole so the steel is captured by the cast-metal detail in the head.

Roughed the holes on the BP, and fine tuned with the die filer

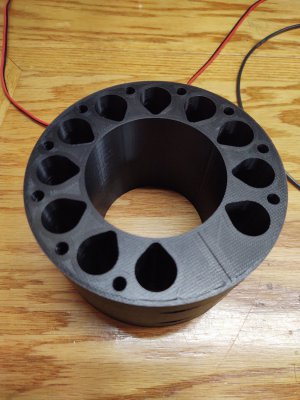

View attachment 448679

My dad passed away 4 years ago, mom last year. Going through their house, I found my dad had an Indestro riveting tool with a punch for tubular rivets. It's been a nice addition to my toolbox, I reproduce a few Erector set parts that use tubular rivets, the punch works much better than a ball peen hammer. Anyway, punched a couple of 5/32" holes in the stainless and drilled through the plastic blades. Peened over a couple of stainless tubular rivets and proceeded to cause much harm to many weeds! Full disclosure, the stainless blades work great on weeds and small saplings up to 3/4" diameter, but at 0.036" thick, the tips will bend so I'll probably replace them with some 1/16" thick stainless. Oh, don't ask me how I know, but they also work great cutting through vinyl siding!

View attachment 448680

View attachment 448681

View attachment 448682

Maybe paint the tips orange for safety?

View attachment 448683

Thanks for looking, Bruce