- Joined

- Apr 28, 2014

- Messages

- 3,590

Hey gang!

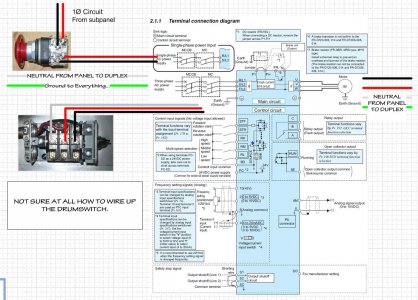

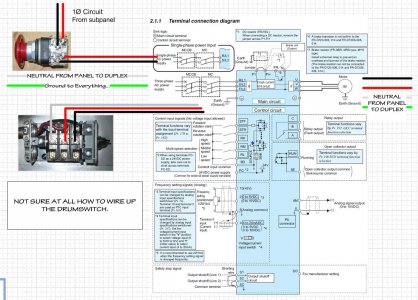

I need some help connecting the dots. I am a tad lost trying to wire up the Mitsu VFD. (Completely actually.)

I do wish that I understood electrical systems and schematics better.

I finally got the garage re-wired and dropped a new circuit of 10/4 over to the mill.

I'm trying to layout all the wiring and then make up the mounts and harness(es) as required.

- VFD is a Mitsubishi FR-D7205-070-NA.

- Motor on the Bridgeport is wired for 240v.

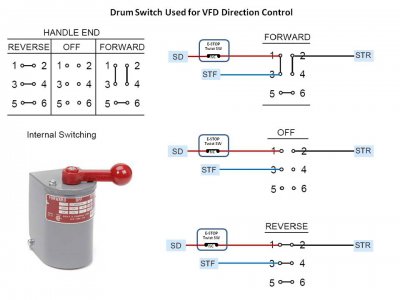

- I would like to keep the drum switch (just because old habits die hard...)

- I'm adding a 'Panic button'. to the two hots coming from the sub-panel before they connect to the VFD.

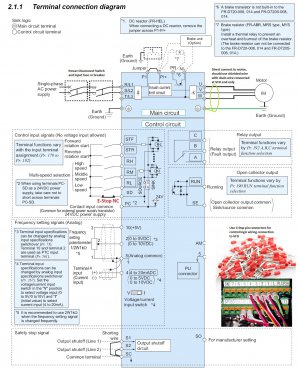

Would anyone hazard a guess as to how I should connect the three wires from the Bridgeport motor to

the 'U', 'V', & 'W'? There were Black, Red and White coming from the motor to the drum switch.

I've poured over dozens of diagrams on the web and can't figure out how to wire up this VFD for the drum switch.

I'm figuring that it has to with the 'STF', 'STR', & '???' (maybe the 'SD')

I also need to know how the green/orange connectors on the the front work, I've never seen this type before.

I'm assuming it's just push the wire in, and then use the orange bar to release, but again my confidence level is pretty low.

Thanks in advance, _Dan

I need some help connecting the dots. I am a tad lost trying to wire up the Mitsu VFD. (Completely actually.)

I do wish that I understood electrical systems and schematics better.

I finally got the garage re-wired and dropped a new circuit of 10/4 over to the mill.

I'm trying to layout all the wiring and then make up the mounts and harness(es) as required.

- VFD is a Mitsubishi FR-D7205-070-NA.

- Motor on the Bridgeport is wired for 240v.

- I would like to keep the drum switch (just because old habits die hard...)

- I'm adding a 'Panic button'. to the two hots coming from the sub-panel before they connect to the VFD.

Would anyone hazard a guess as to how I should connect the three wires from the Bridgeport motor to

the 'U', 'V', & 'W'? There were Black, Red and White coming from the motor to the drum switch.

I've poured over dozens of diagrams on the web and can't figure out how to wire up this VFD for the drum switch.

I'm figuring that it has to with the 'STF', 'STR', & '???' (maybe the 'SD')

I also need to know how the green/orange connectors on the the front work, I've never seen this type before.

I'm assuming it's just push the wire in, and then use the orange bar to release, but again my confidence level is pretty low.

Thanks in advance, _Dan