- Joined

- Sep 3, 2011

- Messages

- 478

Yes, that's to lock the knee when you need a little extra rigidity.

The paint job is looking good!

Cal

The paint job is looking good!

Cal

Cal, I tried to find the original source from the PM forum you referenced, but I ran out of patience in the 77 pages there. Could you get me to it? Thanks!I'm not picturing how the M-head was attached to the machine. Can you elaborate? Oiling the adapter tube won't affect it's holding power.

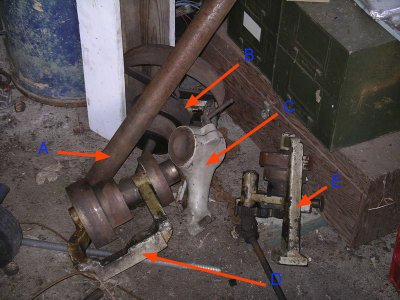

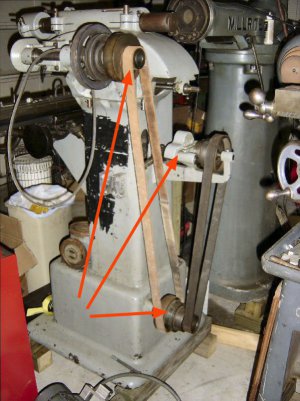

If you look at the photos that I posted of my 1/2, you can see how it was done there. It had a gearbox that sat between the motor and the pulleys that drove the horizontal shaft into the right angle drive. You could just mount a 3-phase motor where the gearbox is and change the flat belt pulley on the shaft to a double-belt pulley, like that used on my old machine. Run the motor with a VFD. It should be very straight forward to make a bracket for the motor. I would use at least a 3HP motor so that you still have some torque when you dial it down.

Here's how another guy did it:

http://www.practicalmachinist.com/v...86209109-van-norman-came-cold-l-img_4612a.jpg

http://www.practicalmachinist.com/v...an-came-cold-vn_one_half_table_feed_belts.jpg

Cal