- Joined

- Jan 7, 2014

- Messages

- 113

Hi All,

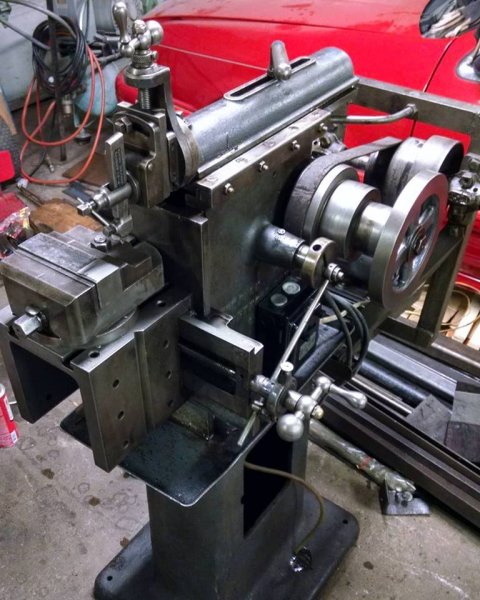

I have been playing around with my "new" 7" rhodes shaper and I am finding that the parts are out quite a bit. I pulled the vise and ran an indicator over the table and it appears to be .005-.006 out. I pulled up on the ram when it was fully extended and did not get much movement. I think the solution is to true up the table since I cannot see a good way to shim up the table/box. I do not have much in the way of experience grinding HSS shape tools. I have ground a couple roughers that work well in Steel. I am guessing that the correct tool to cut the box would be a shear tool? I tried searching around the interwebs but I could not find a book or article that speaks to doing this.

Has anyone trued up the table on their shaper? Advice?

I have been playing around with my "new" 7" rhodes shaper and I am finding that the parts are out quite a bit. I pulled the vise and ran an indicator over the table and it appears to be .005-.006 out. I pulled up on the ram when it was fully extended and did not get much movement. I think the solution is to true up the table since I cannot see a good way to shim up the table/box. I do not have much in the way of experience grinding HSS shape tools. I have ground a couple roughers that work well in Steel. I am guessing that the correct tool to cut the box would be a shear tool? I tried searching around the interwebs but I could not find a book or article that speaks to doing this.

Has anyone trued up the table on their shaper? Advice?