- Joined

- Apr 23, 2018

- Messages

- 6,532

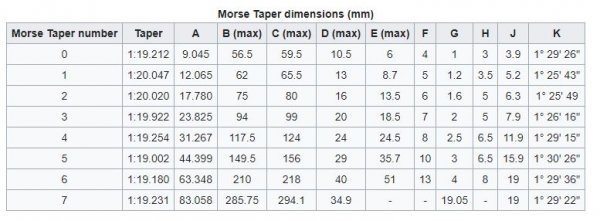

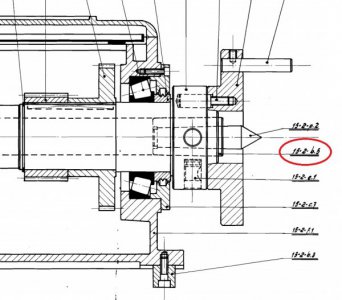

The 1:19,180 looks like a spec for external concentricity. The important thing to notice is the designation in the center, Morse # 3.

Are you sure there? 19 minutes would be about 0.333, since there are 60 minutes to a degree.If it is interpreted as one degree and 19.180 minutes, that is 1.4933 degrees which is the taper angle of MT6.

I think this is a round-about way of saying MT6 is the external taper.

My next task is to find a MT6 object and stick it into the spindle.

The drawing that was sent to me from Italy is for a spindle adapter for spindle to MT3.

The excerpt above is from that drawing.

I believe my spindle is made to the MT6 geometry but not necessarily the MT6 specification.

Fwiw, he measured that taper over about 600 thou, so if he was off just 3 thou over the two measurements, it would account for the difference.Yes, but I don't believe that adapter is actually the correct one for your spindle, it is too small.

That adapter is made to a MT6 taper angle, but that is not close to what you measured your spindle at.

MT6 has a taper of .0521 per inch and yours measured .0477 per inch, that's not even close.

I would contact Riten Industries and see if they can help. They are the experts when it comes to spindle tapers.