- Joined

- Apr 14, 2014

- Messages

- 3,148

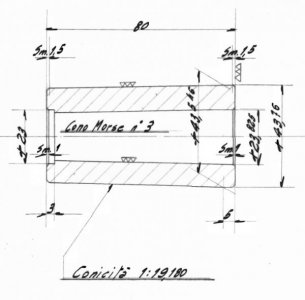

Just keep in mind the numbers in the chart are those at the ends of the prescribed length. As an example the #5 is 1.4750 diameter at the small end and 5.19" from that point should be 1.7480" in diameter. If the length of the taper is shorter than 5.19" it will affect the diameter at each end. I would bet the taper in the spindle is less than the full 5.19" long