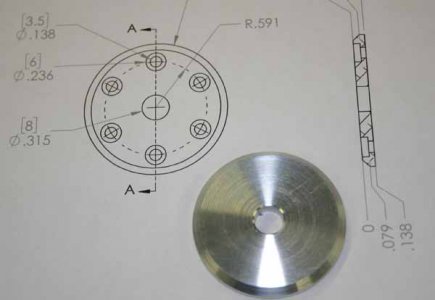

I was trying to solve an issue over on another forum that seemed simple enough. Bond some brass shim to regular steel. What I wasn't expecting is how problematic this would be. Here are some pictures. The parts were very lightly scuffed & squeaky clean with non-oil thinner. My first attempt was #680 retainer which is 0.015" gap fill. Next day the brass basically fell right off, yet the adhesive was hard & cured on the steel. Hmmm...

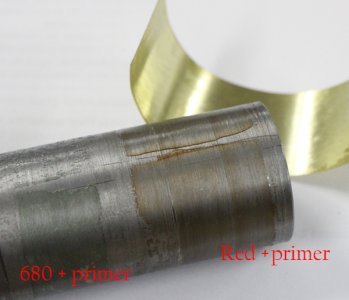

Second attempt I tried 2 different strips, one with red 'permanent' Loctite and the #680 again, this time with their primer/promoter sprayed on the brass. Exact same result. Its like the brass surface is a natural releasing agent. Just pops off when the tape is removed. Brass is about 56% copper + 38% zinc. Bronze is about 85% copper + 10% tin (both vary by alloy). Maybe its the zinc? All I know from my own experience is C544 bronze Loctite's very aggressively in aluminum. Kind of caught me off guard compared to working time steel on steel. So either 'brass' shim stock is something funky which I doubt or there is something about brass.

What am I missing? Who here has Loctited brass to steel? I did some literature searching on Henkel website, they make reference to purple based on certain conditions, but nothing in big bold letters saying their other compounds basically wont work.

Second attempt I tried 2 different strips, one with red 'permanent' Loctite and the #680 again, this time with their primer/promoter sprayed on the brass. Exact same result. Its like the brass surface is a natural releasing agent. Just pops off when the tape is removed. Brass is about 56% copper + 38% zinc. Bronze is about 85% copper + 10% tin (both vary by alloy). Maybe its the zinc? All I know from my own experience is C544 bronze Loctite's very aggressively in aluminum. Kind of caught me off guard compared to working time steel on steel. So either 'brass' shim stock is something funky which I doubt or there is something about brass.

What am I missing? Who here has Loctited brass to steel? I did some literature searching on Henkel website, they make reference to purple based on certain conditions, but nothing in big bold letters saying their other compounds basically wont work.

Attachments

-

IMG_3212_edited-1-1.jpg45.2 KB · Views: 27

IMG_3212_edited-1-1.jpg45.2 KB · Views: 27 -

IMG_3213_edited-1.jpg220.2 KB · Views: 27

IMG_3213_edited-1.jpg220.2 KB · Views: 27 -

IMG_3215_edited-1.jpg190.9 KB · Views: 24

IMG_3215_edited-1.jpg190.9 KB · Views: 24 -

IMG_3216_edited-1.jpg247.1 KB · Views: 22

IMG_3216_edited-1.jpg247.1 KB · Views: 22 -

IMG_3218_edited-1.jpg227.2 KB · Views: 21

IMG_3218_edited-1.jpg227.2 KB · Views: 21 -

IMG_3217_edited-1.jpg278.8 KB · Views: 23

IMG_3217_edited-1.jpg278.8 KB · Views: 23 -

IMG_3219_edited-2.jpg216.5 KB · Views: 25

IMG_3219_edited-2.jpg216.5 KB · Views: 25