First off, the guages: The triangular device is fine for Imperial threads. It can be used to determine pitch of Whitworth threads but will show gaps where it is 60 degree and Whitworth is 55 degrees. The two smaller guages are both Metric. They will be 60 degrees and in most cases will determine thread pitch fine. The "flat" guages are called colloquially "fish tails". I don't know the proper name but fish tails is well known in both the hobby and professional arenas. They are guages for use in grinding threading tools and setting up threading tools on the lathe.

Threading is generally done with the compound set to 29 degrees so that most of the work takes place on one side of the tool. It can be done straight in but each pass will be smaller, 0.005 vs 0.010 inch. It is mostly a matter of skill level as to just how deep. The first pass, called a "scratch" pass, is just deep enough to scratch the surface. That is then checked to verify that you are indeed cutting the desired pitch.

Once the compound is set up, the actual tool must be set to 90 degrees to the chuck. The notches in the fish tail guage come into play here. The guage is held against the work to be threaded and the tool comes into the notch. When it is properly aligned, the tool will fill the notch with no gap on either side. The fish tails are not really pitch guages, but are a necessity when setting up threading. Once you "get used" to the odd shape, they make good squares for small work as well as other uses.

As regards "

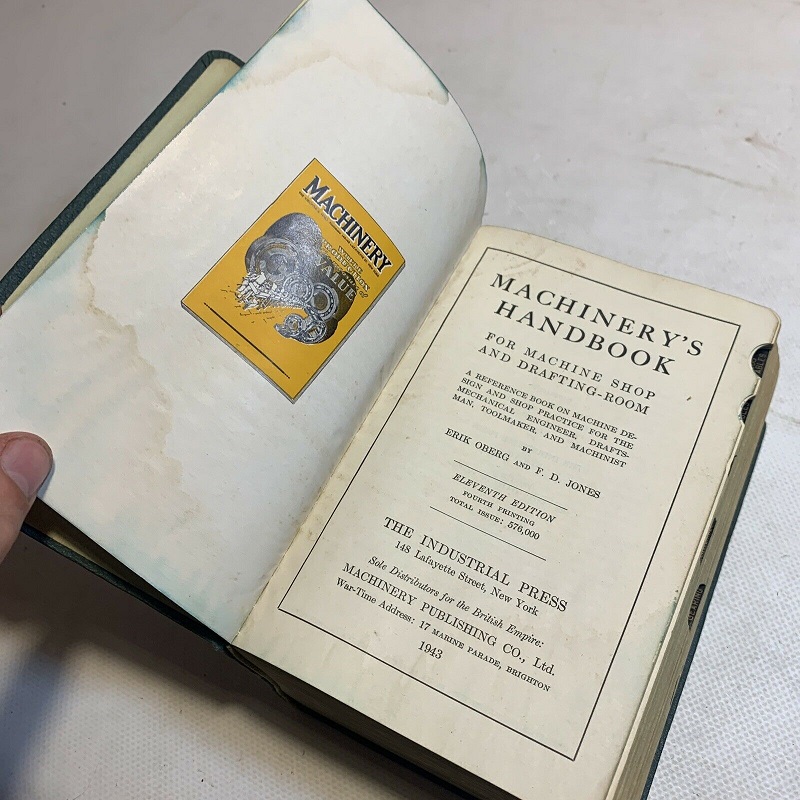

Machinery's Handbook", the book is a "bible" of machining information. The copy you have shown is a good range, containing a little, but not all current, metric information. There is some toss-up about the usefulness of a guide. It is indeed handy for the occasional user but is not a requirement. Think of "Encyclopedia Brittanica", would you need a "guide" for that, or just dive in and prowl? Machinery's Handbook equates to the encyclopedia in that respect.

Most copies come from estates of old school machinists that didn't need a guide. They knew what they were looking for. And book sellers on eBay may know books but not necessarily machinery. The listed price seems a little high, but not overly so. Things are getting more expensive lately. I would say to go for it. If you should stumble over the guide book, it might be a good purchase. Or not, that is a personal call. The Handbook is the big issue.

I have several copies of the Handbook, but don't have a Guide. I am not a machinist by trade, I

am was an industrial electrician. A master of my craft long ago, not so much today. I used Machinery's Handbook

almost as much for electrical work as for mechanical work. A guide never entered into the equation. An example is EC&M controls, before being bought out by Sq D. There were many "custom" threads in use where a 60 degree thread form was not suitable to the situation. This is where the Handbook becomes useful.

I won't say that higher IQ comes into play, but those that need the Guide are,

to me, wannabes to the craft. They aren't so much a machinist as someone that wants to be called one. I'll leave the final call to your discretion as you become more experienced. I am a master of my craft of old, I don't need to be called something else.

EDIT: If you flip over the smaller, Metric guages, you may find that they also work for Whitworth. That guage looks mightly familiar.

.