- Joined

- Dec 18, 2019

- Messages

- 6,480

Make one of theseAs soon as I get a tile saw big enough to cut through it

Make one of theseAs soon as I get a tile saw big enough to cut through it

I guess that means you’re in line for a piece of granite too?Make one of these

Looks like I just bought the same set.I wanted to try these kind of tool bits... so bought a cheap set to play with the HF lathe...

View attachment 380127

Although I'd love to say yes, not really. (No place left in the shop!) I just thought a homemade diamond saw like that was really cool. There have been times when I would have liked to cut granite like that. Such as when I needed to cut granite edging, did it the old fashioned way, with a chisel. Came out good enough.I guess that means you’re in line for a piece of granite too?

WHOLLY GRANITE BATMAN... do you have a need for a plate that big?I think this qualifies as a tool. 83" x 55"x13", about 7200 lbs of granite surface plate. It's actually the base from a former CMM.

View attachment 381061

I really need to sell this trailer to stop myself from picking up these large random finds

Need? You mean I have to justify buying tools with a need? What happened to buy once cry once?WHOLLY GRANITE BATMAN... do you have a need for a plate that big?

Do you know what kind of stand you're going to have to build to support that monster....

WOW... WOWSER...

No you don't need a NEED... just curious if you were planning on working on big stuff, like engines, (That's even too big for an engine)... I guess I don't know what you would stick on a plate that size..Need? You mean I have to justify buying tools with a need? What happened to buy once cry once?

I figure 3/16 x 4 x 4 square tube.

I was looking for a 3’ x 4’. This came along at a better price.

Looks like I just bought the same set.

Can I ask you to look at yours?

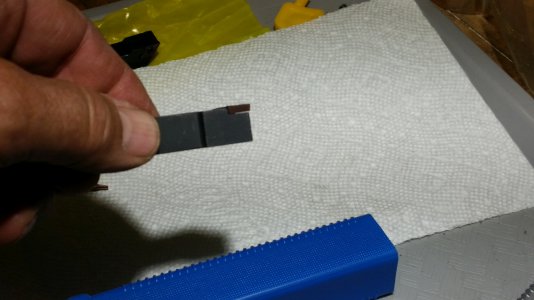

I have 2 problems, and one... well not sure. I would not think that the boring bar needs a negative rake.. but mine has it...

The 2 problems are the left and right screws are in the wrong spot causing the carbide to lift.

I am not sure if I want to keep them. I think I can fix the RH one, the left will require a lot more elbow work...

View attachment 381064View attachment 381066View attachment 381065

I played with the boring bar, and the RH tool since the RH was hitting the holder at the tip. Nice cutting, and I am breaking a chip on the same material that HSS, CNMG, and WNMG were giving me fits on. So that's a win. The other thing is it didn't break the bank, but now I wish I had spent more on the 16mm, rather than the 12. I could have reduced the bottom and gotten a beefier piece of carbide... oh well.

We'll see if the seller will replace the one holder.

My new shop construction tentatively starts Jan 3rd. I’m already working to fill it up!!I'm GREEN with envy.. But I would have to build a new shop to find a place for that.

Thanks, it looks like your boring bar is also negative rake, that's what I was curious about.Mine are the 12 mm ... Here is the link to the set I got: 4 Piece 1/2" Mini Lathe Indexable Carbide Turning Tool Set.

I think you should return those and have them replaced for a new set... mine do not have that issue... Here, take a look:

View attachment 381067

View attachment 381068

View attachment 381069

View attachment 381070