- Joined

- Jan 25, 2015

- Messages

- 2,558

Apologies if this is in the wrong forum, I didn't see a better place to post it.

I'm at the point where I need to run all the fuel and brake lines for my 83 mustang.

Suffice to say, using the "standard" type flare tool for that many flares isn't really an option:

They're good for a couple flares, but do a lot of them and you get pretty sore hands and eventually it starts slipping and just generally destroys itself with lots of use. It also doesn't help that every day I'm a little bit older and that means....ahem.....weaker.

The screw you see in the clamp portion is steel and the casting is soft iron, so it just eats itself up after a certain amount of use and plain wears out. I've got to plumb every single brake and fuel line on the car, so I need a better way than the hand operated brute force "crush" type flare tools.

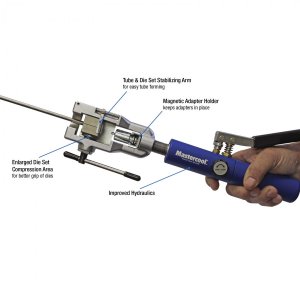

I'd like to pick up a bench mounted unit or the hand held hydraulic unit, but they're hella expensive. You'd be lucky to get a tool like those for under 500+bucks Cad and you're more likely to spend 700 cad once you get it shipped, pay the duties, taxes, etc. That may not seem like much considering the job I'm looking at, but its a scootch more than I want to (actually it's a lot more than I have to) spend. The hydraulic units all look like a variation of this:

It's basically just a small hand pump and ram that pushes a couple forms together and forces the tube into a flare.

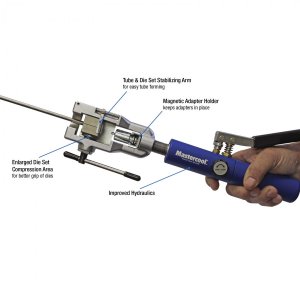

The key parts are the die sets, which hold the tubing and form the flare. The dies look like this:

The blocks you see are actually split so you can put the tube in and then remove it after the flare is formed. They're held together by a screw/clamp arrangement in the housing assembly.

The hydraulic part of the tool just applies the force, the dies do the important work. Here's a vid on how it work if you are interested:

So, cash poor means I have to get "creative".

I'm thinking about making a brake flare tool using my porta-power ramset.

It would, obviously, be bench mounted so size isn't a factor. I don't need to use it "on car", so that's ot a factor either.

Making the housing to hold the dies shouldn't be too hard, just a bit of work on the mill and some 1018 (which is probably stronger than the "bought" tool, as it's a cast assembly).

It's the dies that I'm wondering about. They're not cheap either, just over 200 cad for that set in the pic above. But that's a bit more manageable than 500-700 Cad. Should I try to make the dies or just suck it up and buy a set?

I do have several of the crush types that are in various stages of worn out/broken, I suppose I coudl always sacrfice a couple broken ones and cut out the parts I need to make a hydraulic flare tool. I don't need many different sizes, so I probably have lots of pieces to build from.

As mentioned, I've got several of the "tube crusher" flare tools, so geometry is something that I can measure off what I have here. The dies themselves look like pretty simple thing to make.

I guess I'm looking for input on how I may machine out a set of dies and perhaps the holder for the hydraulic portion.

Again, I dont have the money to just "suck it up and buy one", so please don't suggest that. If I had the money, I'd have already bought a set.

I'm at the point where I need to run all the fuel and brake lines for my 83 mustang.

Suffice to say, using the "standard" type flare tool for that many flares isn't really an option:

They're good for a couple flares, but do a lot of them and you get pretty sore hands and eventually it starts slipping and just generally destroys itself with lots of use. It also doesn't help that every day I'm a little bit older and that means....ahem.....weaker.

The screw you see in the clamp portion is steel and the casting is soft iron, so it just eats itself up after a certain amount of use and plain wears out. I've got to plumb every single brake and fuel line on the car, so I need a better way than the hand operated brute force "crush" type flare tools.

I'd like to pick up a bench mounted unit or the hand held hydraulic unit, but they're hella expensive. You'd be lucky to get a tool like those for under 500+bucks Cad and you're more likely to spend 700 cad once you get it shipped, pay the duties, taxes, etc. That may not seem like much considering the job I'm looking at, but its a scootch more than I want to (actually it's a lot more than I have to) spend. The hydraulic units all look like a variation of this:

It's basically just a small hand pump and ram that pushes a couple forms together and forces the tube into a flare.

The key parts are the die sets, which hold the tubing and form the flare. The dies look like this:

The blocks you see are actually split so you can put the tube in and then remove it after the flare is formed. They're held together by a screw/clamp arrangement in the housing assembly.

The hydraulic part of the tool just applies the force, the dies do the important work. Here's a vid on how it work if you are interested:

So, cash poor means I have to get "creative".

I'm thinking about making a brake flare tool using my porta-power ramset.

It would, obviously, be bench mounted so size isn't a factor. I don't need to use it "on car", so that's ot a factor either.

Making the housing to hold the dies shouldn't be too hard, just a bit of work on the mill and some 1018 (which is probably stronger than the "bought" tool, as it's a cast assembly).

It's the dies that I'm wondering about. They're not cheap either, just over 200 cad for that set in the pic above. But that's a bit more manageable than 500-700 Cad. Should I try to make the dies or just suck it up and buy a set?

I do have several of the crush types that are in various stages of worn out/broken, I suppose I coudl always sacrfice a couple broken ones and cut out the parts I need to make a hydraulic flare tool. I don't need many different sizes, so I probably have lots of pieces to build from.

As mentioned, I've got several of the "tube crusher" flare tools, so geometry is something that I can measure off what I have here. The dies themselves look like pretty simple thing to make.

I guess I'm looking for input on how I may machine out a set of dies and perhaps the holder for the hydraulic portion.

Again, I dont have the money to just "suck it up and buy one", so please don't suggest that. If I had the money, I'd have already bought a set.

Last edited: