-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

- Joined

- Sep 8, 2019

- Messages

- 4,392

- Joined

- Aug 6, 2015

- Messages

- 3,934

Your father's version looks better, and as you noted he made it and the gauntlet has been thrown.

Back in the '90's a processing equipment manufacturer I was buying a boatload of equipment from gave me a box of these that were molded out of FRP with a metal tab inserted to pry under the cap; they also had a slot on the "back" to help pry up tabs on cans (they were changing their logo and wanted to get rid of them):

I was traveling a lot in those days, and passed them out to happy flight attendants (no more broken nails).

So I have been giving this some thought... since I am making it out of stainless steel... I was concerned with the tab on top (for the can opener) to be a safety risk...

Turns out, this design also works with cans... here, take a look (and yes, I need some hand lotion for my dry hands

I should have enough material to try both... will try to make both designs and see if I can make the top one not be a risk for cutting myself with it...

- Joined

- Sep 8, 2019

- Messages

- 4,392

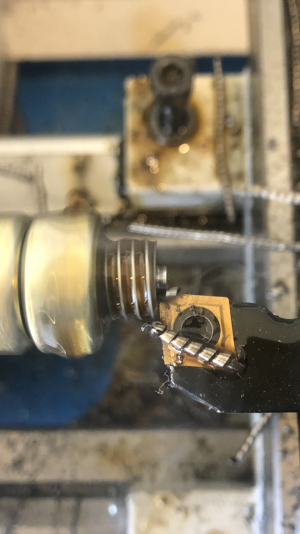

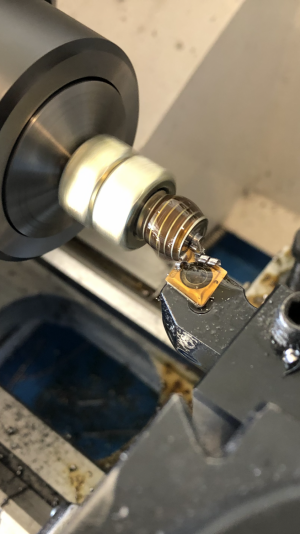

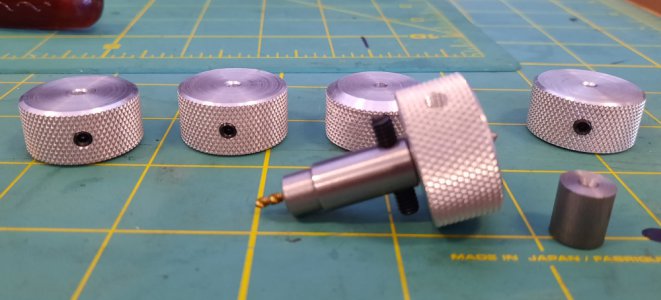

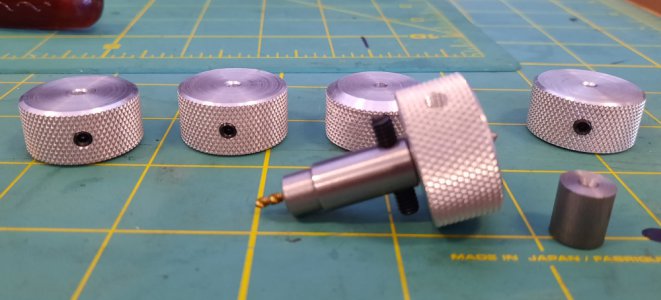

Made a batch of tapping 'knobs' after an idea I saw several places on YouTube for driving tiny taps. (I have some 17-4 that needs #2-56 holes...).

Knob to drive the tap, depth stop, and a little adapter that fits snugly on the back so I can use a spring-loaded tap follower for alignment. Sorry the pic isn't so good...

Knob to drive the tap, depth stop, and a little adapter that fits snugly on the back so I can use a spring-loaded tap follower for alignment. Sorry the pic isn't so good...

- Joined

- Jul 14, 2017

- Messages

- 2,451

White elephant No:1 was in town so it stopped by to check it developed leaks. First was easy oil drain plug got a new copper washer. Second one was at the power steering line, that one got new washers and bolt. Last repair come as a surprise, sway bar link was missing its slave and bolt and i'm sure it was tight. I did changed the link and installed a new bolt tighten it. Few leaks and a sway bar link took me about 3 hours manly because i had to drain and refill the engine oil and power steering.

- Joined

- Sep 5, 2013

- Messages

- 3,223

Left work early today to come home and, errr, work on work things. Something’s not right there….

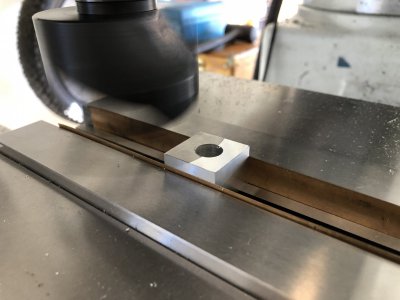

Anyway, quick job that got me back in the shop for a bit. These are magnet cups for holding rare earth magnets. In addition to multiplying the holding power considerably they also make a great way to attach a magnet without resorting to an adhesive. The only trouble is once you get the magnet popped in there it’s a devil to get out again, and the mounting screw is underneath said magnet! So first thing I do is cut two slots in the sides, not a critical width but just enough to get a small screwdriver in and prise out the magnet. Usually I use the Dremel with a cutoff disc but today I had 36 to do so elected to use the miller.

Like I said, nothing critical here in terms of tolerances so a piece of cherry with some pilot holes was easily up for the job. I did four at a time with a 1/4” stagger tooth cutter so only nine changes to get the batch done.

And we’re away. Back to work tomorrow and carry on with the project. Wait a minute, didn’t I just come from there…?

Thanks for looking.

-frank

Anyway, quick job that got me back in the shop for a bit. These are magnet cups for holding rare earth magnets. In addition to multiplying the holding power considerably they also make a great way to attach a magnet without resorting to an adhesive. The only trouble is once you get the magnet popped in there it’s a devil to get out again, and the mounting screw is underneath said magnet! So first thing I do is cut two slots in the sides, not a critical width but just enough to get a small screwdriver in and prise out the magnet. Usually I use the Dremel with a cutoff disc but today I had 36 to do so elected to use the miller.

Like I said, nothing critical here in terms of tolerances so a piece of cherry with some pilot holes was easily up for the job. I did four at a time with a 1/4” stagger tooth cutter so only nine changes to get the batch done.

And we’re away. Back to work tomorrow and carry on with the project. Wait a minute, didn’t I just come from there…?

Thanks for looking.

-frank

- Joined

- Jan 4, 2021

- Messages

- 1,965

My plastic one is shaped slightly differently so can't get the bottle "lifter" under a tab (but if you flip it over you can make it work on a tab, just not as easy as the slot).So I have been giving this some thought... since I am making it out of stainless steel... I was concerned with the tab on top (for the can opener) to be a safety risk...

Turns out, this design also works with cans... here, take a look (and yes, I need some hand lotion for my dry hands, shut up! )..

View attachment 424741

I should have enough material to try both... will try to make both designs and see if I can make the top one not be a risk for cutting myself with it...

You should be able to break the leading edge of the slot enough so it won't get confiscated by TSA but still function. Although . . . I did have a finger nail clipper confiscated in Quito, Ecuador back in 2011: not because it had the nail file (it didn't), but because of the sharp edges of the cutters – I didn't argue with this logic.

Last edited:

- Joined

- Jan 25, 2015

- Messages

- 2,558

Cleaned, prepped, taped and painted the fj1200 engine:

A couple days to harden up and then I’ll polish the ends of the fins and assorted other bits.

While waiting for the paint to harden, I started polishing the exhaust down tubes:

The one in the back is how they start off. The front is not finished, still working on stripping the old paint and rust off it. The down pipes are actually stainless, so rather than paint them black again I’m going to polish them to go with the kerker cans:

A couple days to harden up and then I’ll polish the ends of the fins and assorted other bits.

While waiting for the paint to harden, I started polishing the exhaust down tubes:

The one in the back is how they start off. The front is not finished, still working on stripping the old paint and rust off it. The down pipes are actually stainless, so rather than paint them black again I’m going to polish them to go with the kerker cans:

Last edited:

- Joined

- Jul 14, 2017

- Messages

- 2,451

Today was a long day in the small garage. My winter daily driver is finally in for repairs. On my last safety inspection passenger side ball joint showed some play but last few day i sterted to feel it in the steering, also the CV boot was ripped and as i found out the sway bar link on that side and the opposite rear had a bunch of play. I did buy new quality ball joint and some time back made a tool for it. This car has never had any of the suspension replaced, i've driven it more than 600 000 km in the last 8 years and it had lots more when i bought it used. So i can't complain the french have made it to last. That said working on it isn't easy. Evry bolt is 2 sizes bigger than on other cars. I had to remove the entire shock and axle to put my big corded impact to unbolt the bolt joint. At this point i had to stop run out of time, i'll continue tomorrow and i'll have to buy 2 stabilizator links.