-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New PM-728V-T Mill

- Thread starter AlanB

- Start date

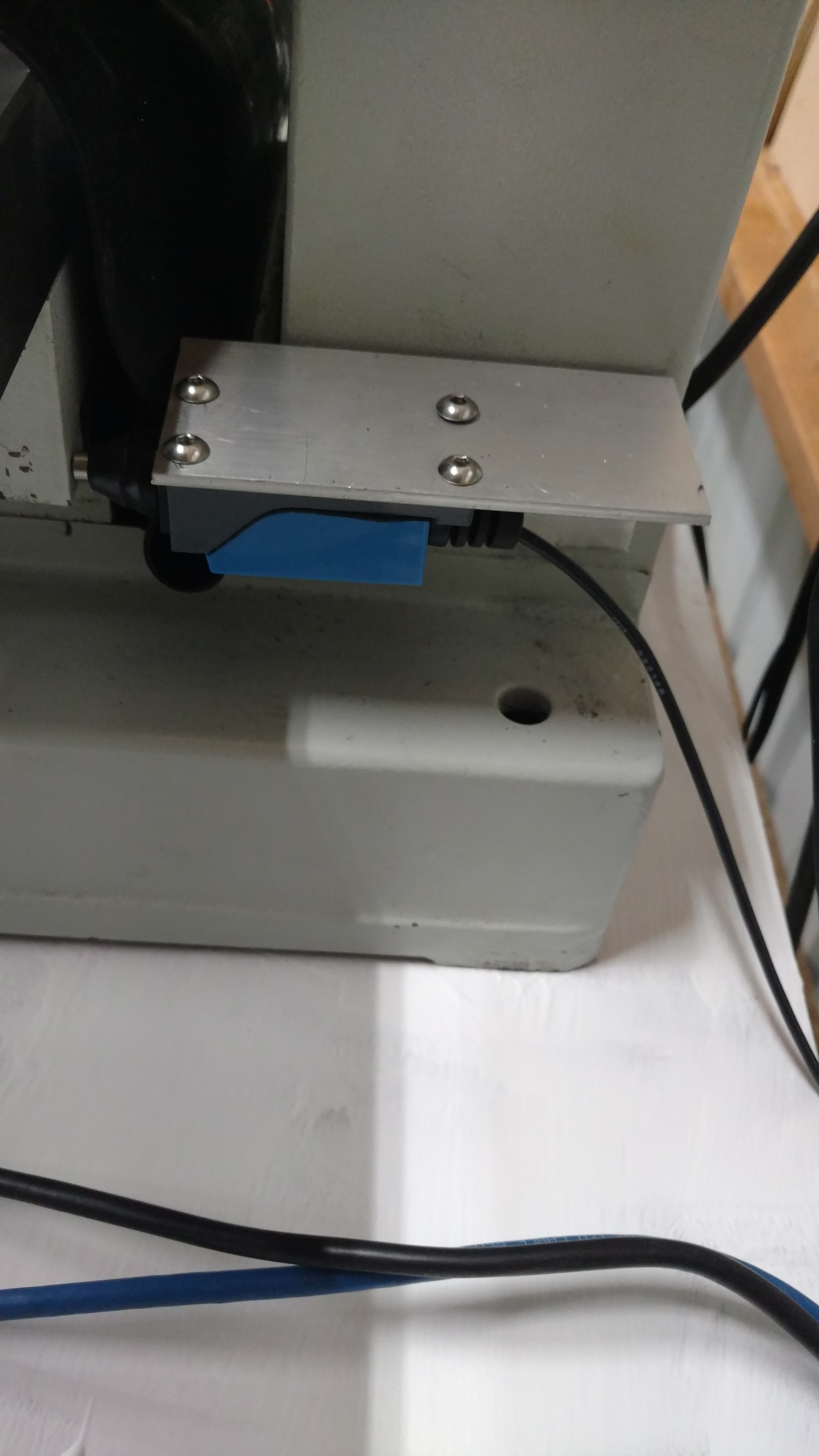

Previously listed as end of July, now listed as "ETA Sept/Oct 2020." Hopefully the manual will be posted earlier, to get an idea of what is involved.I'm looking forward to the PM-728 CNC hardware kit. I for one would not want any particular electronics package included, there are too many choices in motors, electronics and software. I've already collected most of that but a bolt-in hardware kit would really reduce the risk and effort of the mechanics. It's July now so hopefully we're getting close on this kit.

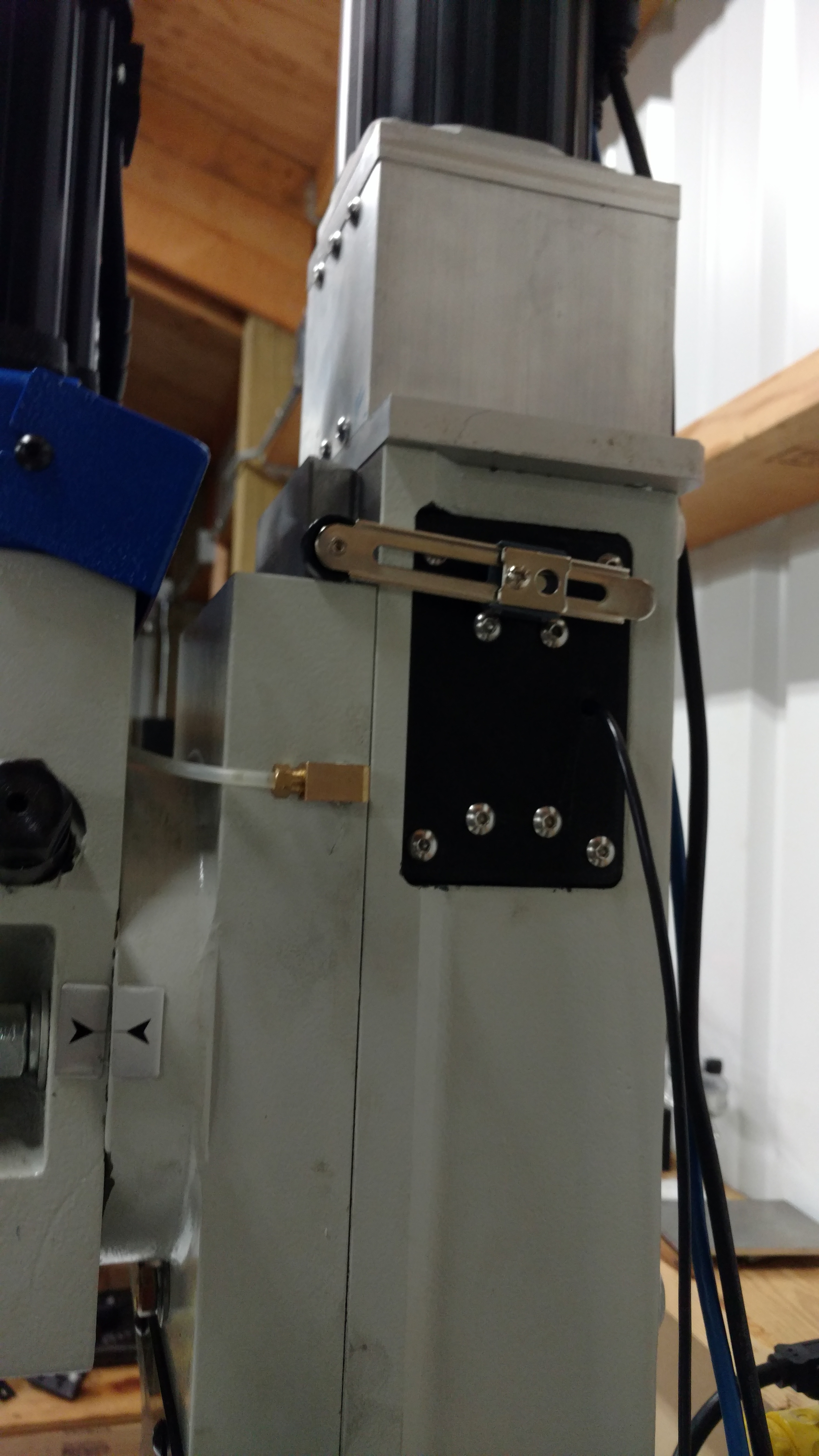

Have been working on it. Have the Home switches installed. Printed a mount for the Z that filled the void from the Z crank.

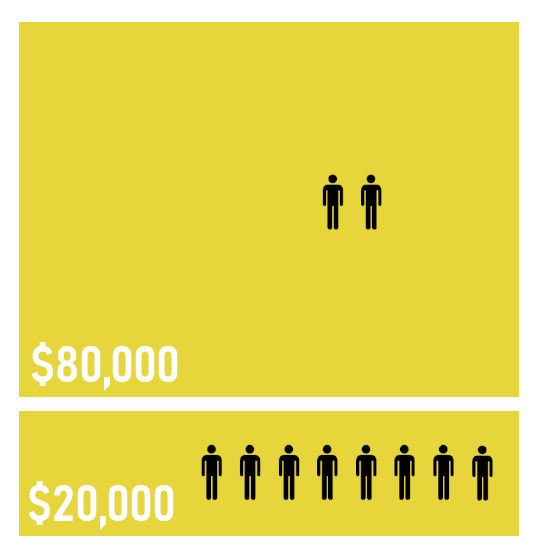

Tried to KISS. The switch has a long arm so it ended up with backoff more than it should be but will work.

Printed a cover for the X switch

Mounted the Y to a piece of angle. Might need to print one to match the others

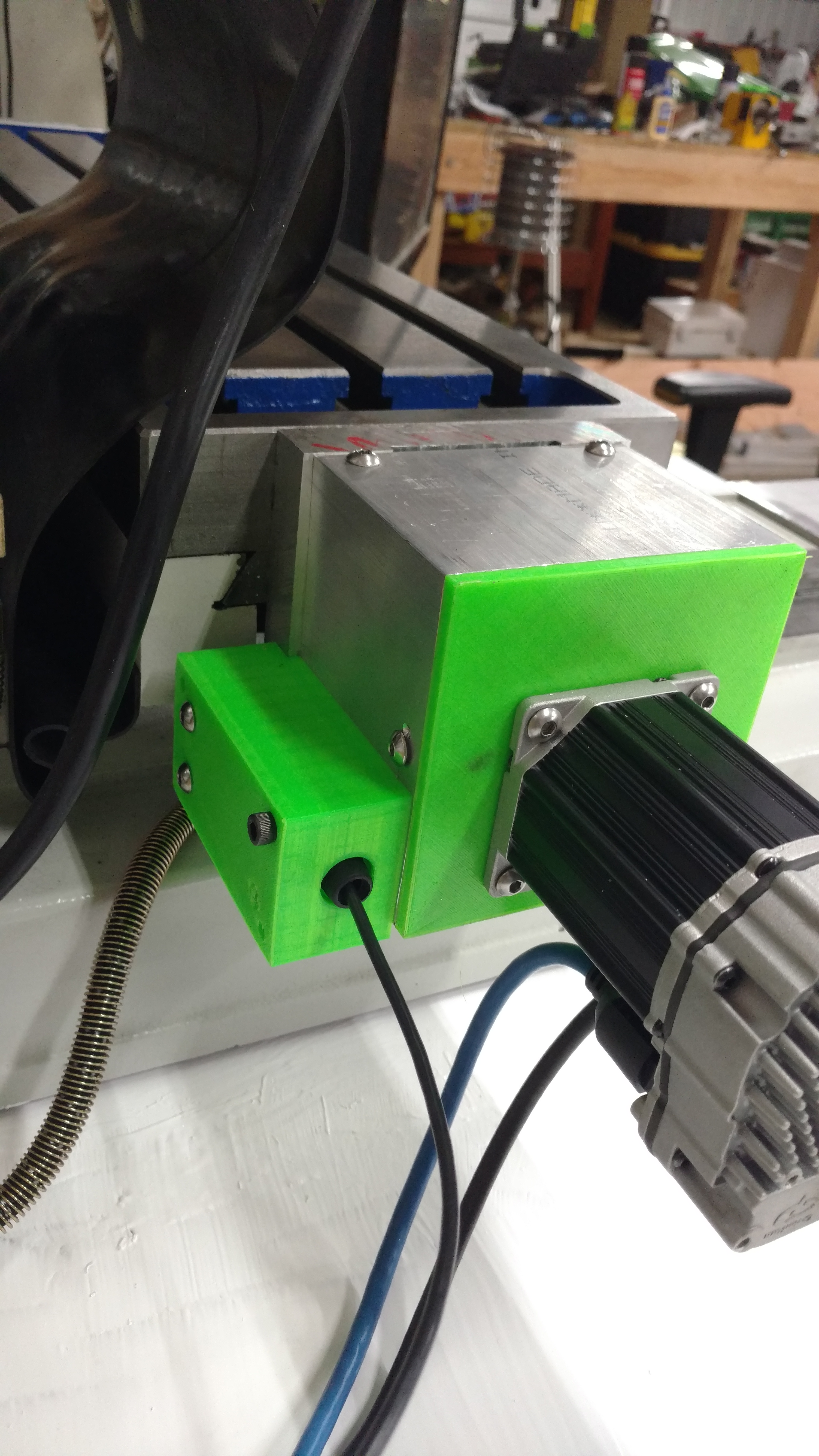

Glad I used a board from CNC4PC to connect the Clearpath servos to the Acorn. The Z servo has an issue with no holding power when not enabled (the head will drop when turned off or disabled). The board has a setting for hardware or software enable. If software is used the head can drop when 'reset'. Switched to the hardware setting and seemed to solve the issue.

Tried to KISS. The switch has a long arm so it ended up with backoff more than it should be but will work.

Printed a cover for the X switch

Mounted the Y to a piece of angle. Might need to print one to match the others

Glad I used a board from CNC4PC to connect the Clearpath servos to the Acorn. The Z servo has an issue with no holding power when not enabled (the head will drop when turned off or disabled). The board has a setting for hardware or software enable. If software is used the head can drop when 'reset'. Switched to the hardware setting and seemed to solve the issue.

- Joined

- Sep 28, 2014

- Messages

- 2

Thanks for posting pics. I'm following the thread very closely since I'm thinking about buying one of these.

If I do I will learn how to run it manually and I would like to do a CNC conversion in the future so this is all very interesting!

If I do I will learn how to run it manually and I would like to do a CNC conversion in the future so this is all very interesting!

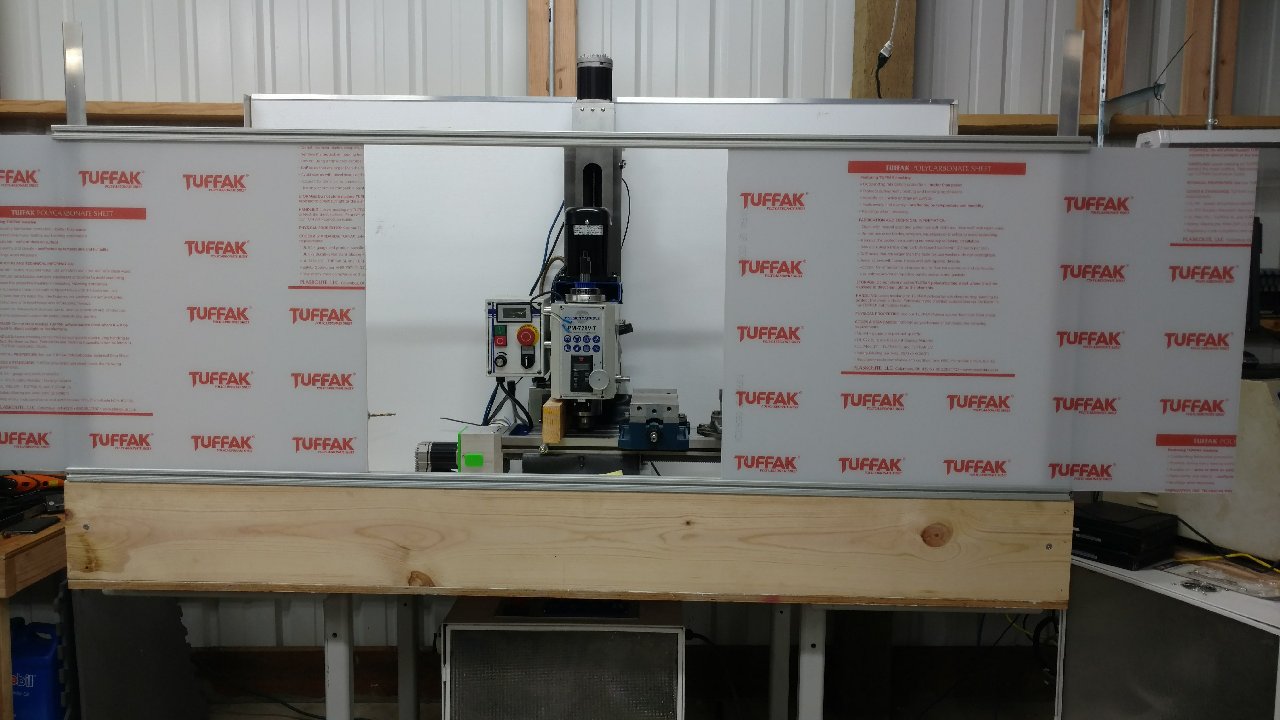

Been sidetracked but working on an enclosure of sorts. Mostly to keep chips in. Maybe some mist, not planning on flood but we shall see.

KISS, used 80-20 extrusion for top and bottom rails for both sides and front doors. I have plenty of room left and right so the doors just slide out. The Sides can slide out also to gain access when needed.

1/4" polycarbonate for front and sides. Corrugated plastic in the back but thinking polycarbonate for that also.

KISS, used 80-20 extrusion for top and bottom rails for both sides and front doors. I have plenty of room left and right so the doors just slide out. The Sides can slide out also to gain access when needed.

1/4" polycarbonate for front and sides. Corrugated plastic in the back but thinking polycarbonate for that also.

It's the name of the companyThat looks great. Excellent idea to use 80-20. Why is it called that anyway?

Robert

T-slot structural framing - Wikipedia

- Joined

- Mar 25, 2013

- Messages

- 4,614

Interesting. This is actually the origin:

en.wikipedia.org

Robert

en.wikipedia.org

Robert