-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1/6th scale 1890's 30ft navy steam cutter (live steam)

- Thread starter tghsmith

- Start date

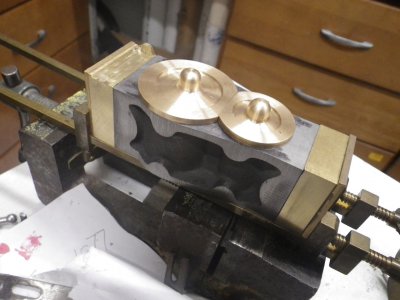

trimmed the cylinder covers to fit and milled the lower ones to get a flat mounting surface on the frames,, added some brass to the LP valve chest to make it a little more US navy and a little less Stuart Turner.. the cast mounting tabs not needed were ground and milled away,, the block was also cleaned up,, looking to see in the block can have a little more length removed,,

Attachments

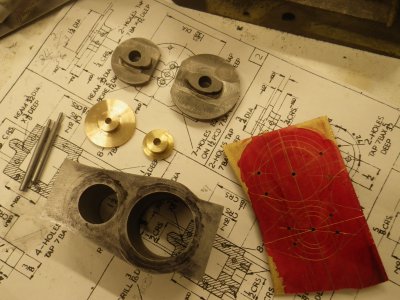

made a drilling jig for bolting the block to the frames, added some piston rod guides to aid alignment,, drilled, tapped and reamed.. everything fits.. lots of excess casting to trim away.. starting to look a little more promising..

Attachments

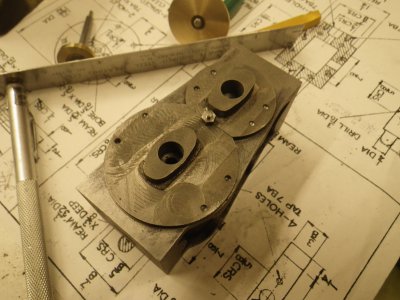

found my castings for the valve shaft/way bar we problematic,, started to make a pair from stock,, they still need the mounting feet soldered in place, hole drilled for the way shaft, outside curves milled and filed.. but they will actually work and look more like the prototype fittings..

Attachments

- Joined

- Apr 28, 2014

- Messages

- 3,590

*Wow*.

This projects makes what I'm thinking of doing someday completely bush league.

This projects makes what I'm thinking of doing someday completely bush league.

made a fixture to to center the rotary table chuck,, seems to work simple and well,, been busy with other things but did get some work done on flange and guides..

Attachments

learning how to do tight bends in copper tube,, shopmade mandrel required, cerro-bend can be reused,,have extra tube,, getting two bends the correct distance is a pain, swearing required,, lots of annealing,, finally got a good pipe and it all soldered up well..