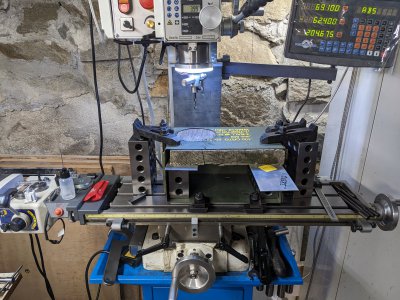

Can anyone suggest an efficient/better/easier method to cut a clean, accurate, 100mm hole through 5mm (or thicker) acrylic sheet on a SIEG SX2 mill? I don't own a boring head and as the workpiece is 185mm x 185mm, it's too large for a 7x12 mini-lathe otherwise it could be bored out in a 4-jaw chuck.

I've done this previously by drilling a circle of holes, knocking out the centre disk then finishing off the ID with a cutter in the mini-mill using a standard 8mm shank mini-lathe lathe tool. It's crude but works quite well as long as the cuts are small (not to mention the fact that the tool has to be adjusted manually). I'm just wondering what tips or tricks there might be for doing this (sans boring head).

TIA

Trevor

I've done this previously by drilling a circle of holes, knocking out the centre disk then finishing off the ID with a cutter in the mini-mill using a standard 8mm shank mini-lathe lathe tool. It's crude but works quite well as long as the cuts are small (not to mention the fact that the tool has to be adjusted manually). I'm just wondering what tips or tricks there might be for doing this (sans boring head).

TIA

Trevor

Last edited: