-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VN 10in Vertical Dividing Head Restoration.

- Thread starter BROCKWOOD

- Start date

You can see the two drain plugs at the bottom of the DH. Second picture shows the spanner inserted. Made it a nice snug fit and tall enough to clear the recessed walls of the DH.

I made the wrench from 3/16 dowel pins pressed into a piece of 1018 or 1045 (don't remember) from the scrap bin. Then a quick hardening with a torch and Kasenit. Just a quick and dirty machining job to get'r done.

I made the wrench from 3/16 dowel pins pressed into a piece of 1018 or 1045 (don't remember) from the scrap bin. Then a quick hardening with a torch and Kasenit. Just a quick and dirty machining job to get'r done.

Dowel pins: 3/16 by 1 inch long

CTC between pins: 1.124 (would verify this dimension on your DH)

OAL: 1.135

Major OD: 1.622

Hex was machined to fit a 1 inch socket.

The dimensions just turned out the way they did. Nothing planned except to make sure it fit into the recess without slop and the pins lined up.

CTC between pins: 1.124 (would verify this dimension on your DH)

OAL: 1.135

Major OD: 1.622

Hex was machined to fit a 1 inch socket.

The dimensions just turned out the way they did. Nothing planned except to make sure it fit into the recess without slop and the pins lined up.

Thank you Sir! I've already set aside the dowels for this wrench & I have plenty of 1.5" bar on hand. Just working up to taking my 84lb vise off the carriage & putting the tool post in it's place on my lathe / mill combo. Maybe you can help answer a question I have about the input. See, I have a spring washer - but no clue where it goes. Does the crank handle only get pinched into place or is there a retaining bolt & washer? OLD STEAM POWERED MACHINE SHOP 46 shows a Van Norman no10 Vertical Dividing Head!

- Joined

- Jan 2, 2016

- Messages

- 1,953

Man, I knew I should not have clicked back on this thread. Now my jealousy bug has been bitten. Only recourse now, is to go watch youtube, and drink a beer.

Good job, I like it. Thanks for sharing.

Thanks for sharing.

Good job, I like it.

Thanks for sharing.

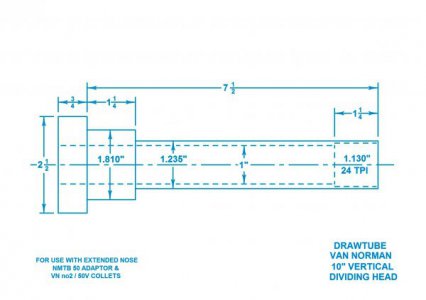

Thanks for sharing.So this dividing head, just like my mill uses NMTB 50 tool holders. That's a good thing. I know, I know, 40 & especially 30 are easier to find & cheaper to buy. Well, there are NMTB 50 adaptors for the use of Van Norman no2 / Hardinge 50V end mill holders & collets. Quick rant: I don't want to collect collets for ER this or ER that or R8 or any of them. Well, I have collected the VN no2 collets & have the drawbars for both the mill & this dividing head. They are different lengths. Not on purpose at all did I collect them. It just worked out that way to the point that I passed some of the parts on to a friend. All this to share a few pointers, should you see the need to adapt this collet system.

1st are the NMTB 50 adaptors. There is a shallow version & an extended version. Due to the drawbar (drawtube) length, they are not interchangeable.

The dividing head I have uses the extended adaptor with the draw tube that matches. My mill uses the shallow adaptor with the draw tube that matches.

Family pic.

All this to say, be sure what you have will work with what you need. I had no idea that the shallow & extended adaptors called for a different offset in the draw tube length. Now that's my Colombo impersonation for the day.

1st are the NMTB 50 adaptors. There is a shallow version & an extended version. Due to the drawbar (drawtube) length, they are not interchangeable.

The dividing head I have uses the extended adaptor with the draw tube that matches. My mill uses the shallow adaptor with the draw tube that matches.

Family pic.

All this to say, be sure what you have will work with what you need. I had no idea that the shallow & extended adaptors called for a different offset in the draw tube length. Now that's my Colombo impersonation for the day.