- Joined

- Jan 20, 2016

- Messages

- 1,011

I put three 120V florescent "under-counter" kitchen lights in my CNC mill enclosure when I built it 5 years ago. They have plastic covers and the bodys are plastic. I think they are water resistant - not waterproof. The coolant (I guess) attacked the plastic of the covers first and is now disintegrating the bodys. One light has the ballast and wiring completely exposed (they do not run a ground wire either).

In short - I need to replace the lighting ASAP!!

From what I can find waterproof 120V AC LED light bars are pretty expensive. From $120 to over $1,000 each. So . . .

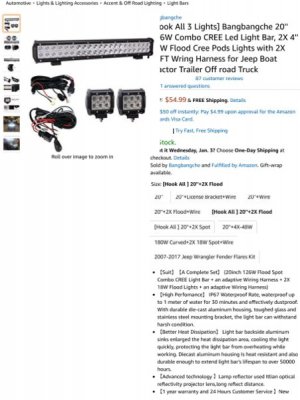

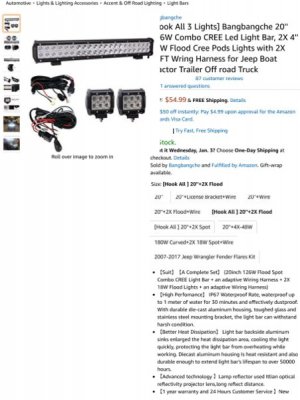

Has anyone tried 12V DC off-road light bars similar to these;

(click to enlarge)

A compatible 12V power supply would bring the total package to somewhere near $100. Much easier to take that $400 or so for the three 120V equivalent lights if they will work.

Anyone know of a reason not to use them?

In short - I need to replace the lighting ASAP!!

From what I can find waterproof 120V AC LED light bars are pretty expensive. From $120 to over $1,000 each. So . . .

Has anyone tried 12V DC off-road light bars similar to these;

(click to enlarge)

A compatible 12V power supply would bring the total package to somewhere near $100. Much easier to take that $400 or so for the three 120V equivalent lights if they will work.

Anyone know of a reason not to use them?