I wasn't looking for a new lathe, as I loved my Craftsman 6 inch, but while out looking for vintage tools and antiques (getting out of my wife's hair, as I do every Saturday) I went to go look at a recuring sale near me that showed some possibilities in the ad. Well, nothing looked to interesting, but there was an old lathe sitting on the ground, but like I said, I wasn't looking right then. But, as I was leaving I overheard someone ask the price "$150" was what I heard, so I slowed down, trying to find out if the other guy was serious, or just asking. Turns out he was just asking, so I quickly jumped. "Will you hold it for $50 while I go and get the rest? I am just going a few miles to the nearest bank."

"Sure, and we can load it for you when you get back."

So, unexpectedly, a new lathe!

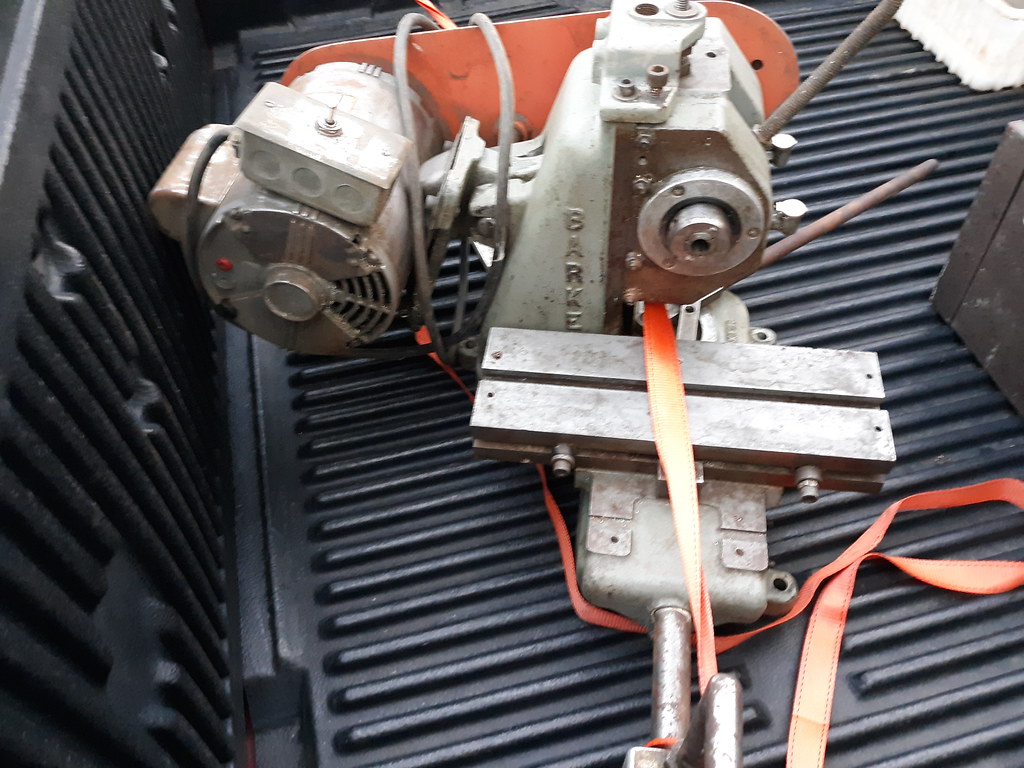

Here it is in the back of my truck.

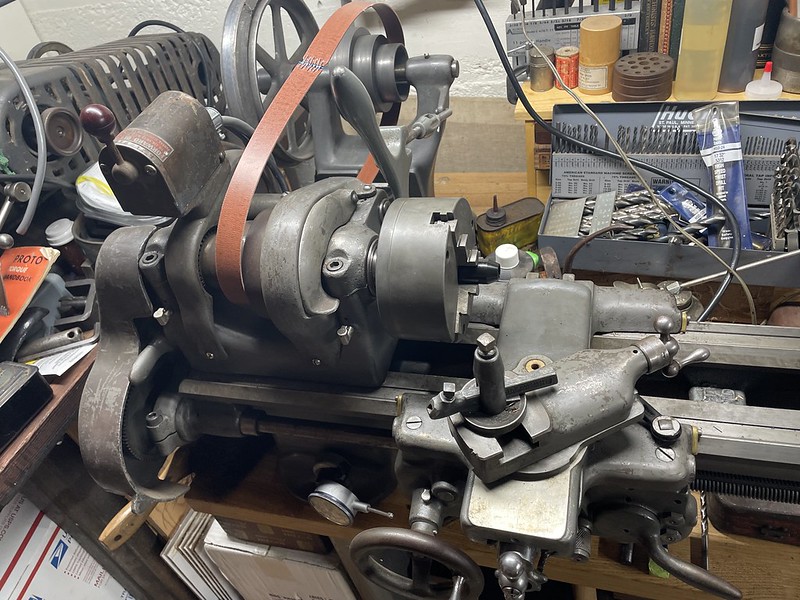

I got it unloaded into the back shed, which was the only place I had room, and then it sat for a few months while I finished up the AMMCO shaper resto I was in the middle of, got the bathroom remodel to a place I was happy with, and was able to start rearranging the tiny basement shop to accommodate this addition. And that is still a massive mess. But here it is loosely assembled on the table I made for it, in the place I finally decided was going to be its location:

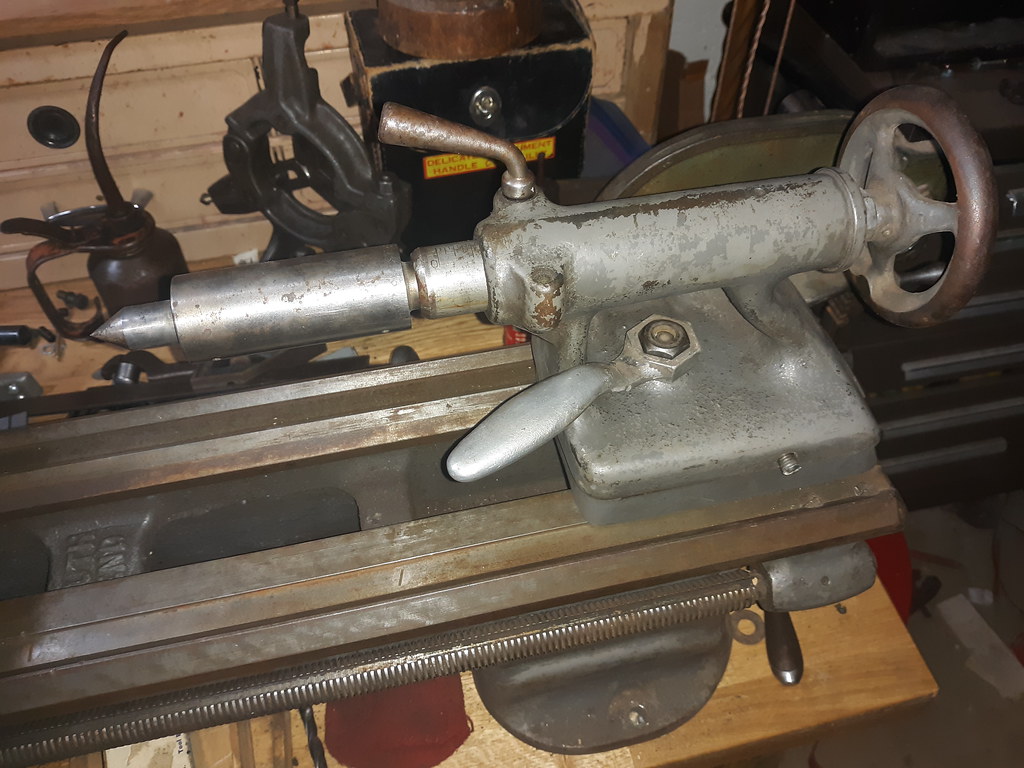

And yes, I know I am not supposed to put anything on the ways. That is why there is a rag and a note pad under things!

Anyway, that is where I am. It came with both 3 and 4 jaw chucks, with a spare set of jaws for the 3-jaw, along with a face plate. An Armstrong tool holder was in the lantern, and it has a couple of the original wrenches also. I have scrounged some replacements for the few broken parts, and a follower rest from a friend. Any other tooling is what I have collected over the years. But, I cannot complain at the price.

My main impressions of it so far are that it has great ways, mostly original paint, and it is filthy. So, right now I am taking it all apart to clean and refresh the old girl, which I have found out is from 1947. I have picked up the rebuild manual, and new felts for it. I might have a belt for the cones, and I need to replace the drive belt. After I sell the 6 inch to my friend Brian, I will pick up a steady rest and change gears, and sooner or later a milling attachment.

I will keep everyone posted as I work everything out.