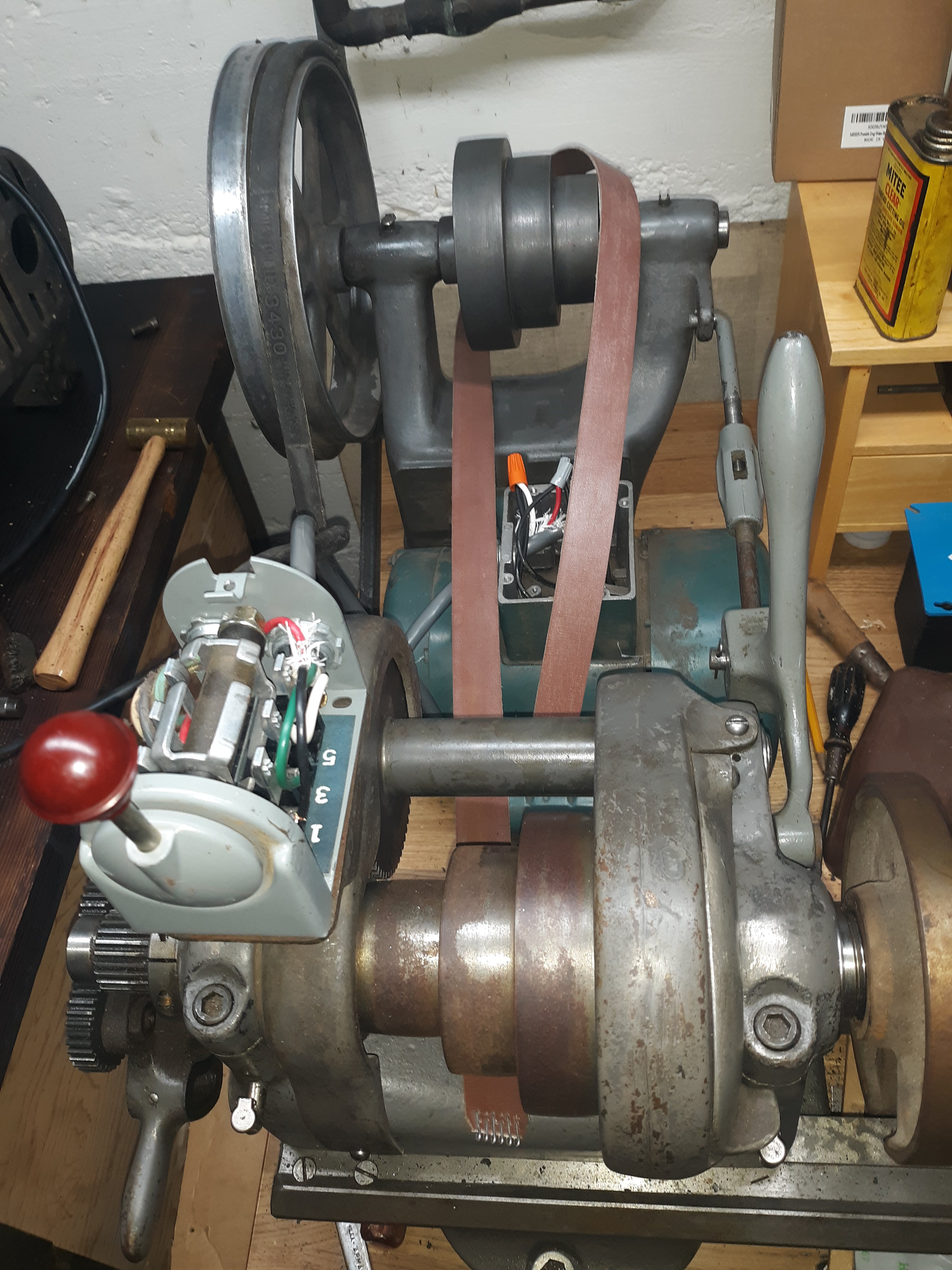

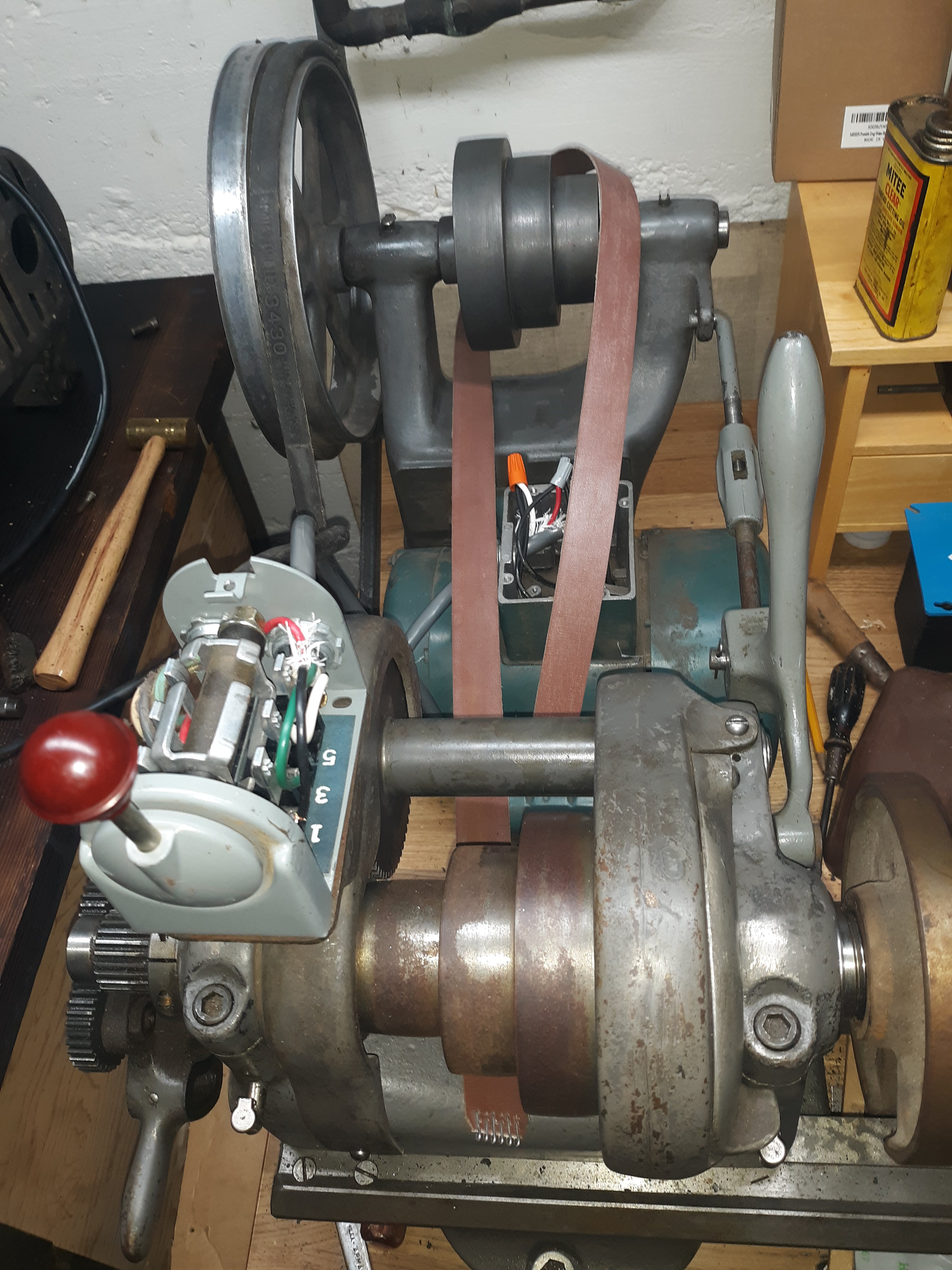

So, lest anyone forgot or thought I had abandend this project, we have gotten the motor mounted, a new Square D drum switch sorted (thanks Mark!):

I do need to fabricate a cover for the motor electric connections box, and the mounting of the SquareD is being one of those fussy little things that should only take a second but is being a pain in the keister; the two mounting screws are the (as far as I can tell) only 12-24 screws on the whole thing, while the matching holes on the switch are sized for 10-32. No big deal, right? But, the spacing is slightly off, wider on the lathe. Ream them out, but screw falls under the machinist chest below the lathe... That sort of thing. No big deal, just annoying.

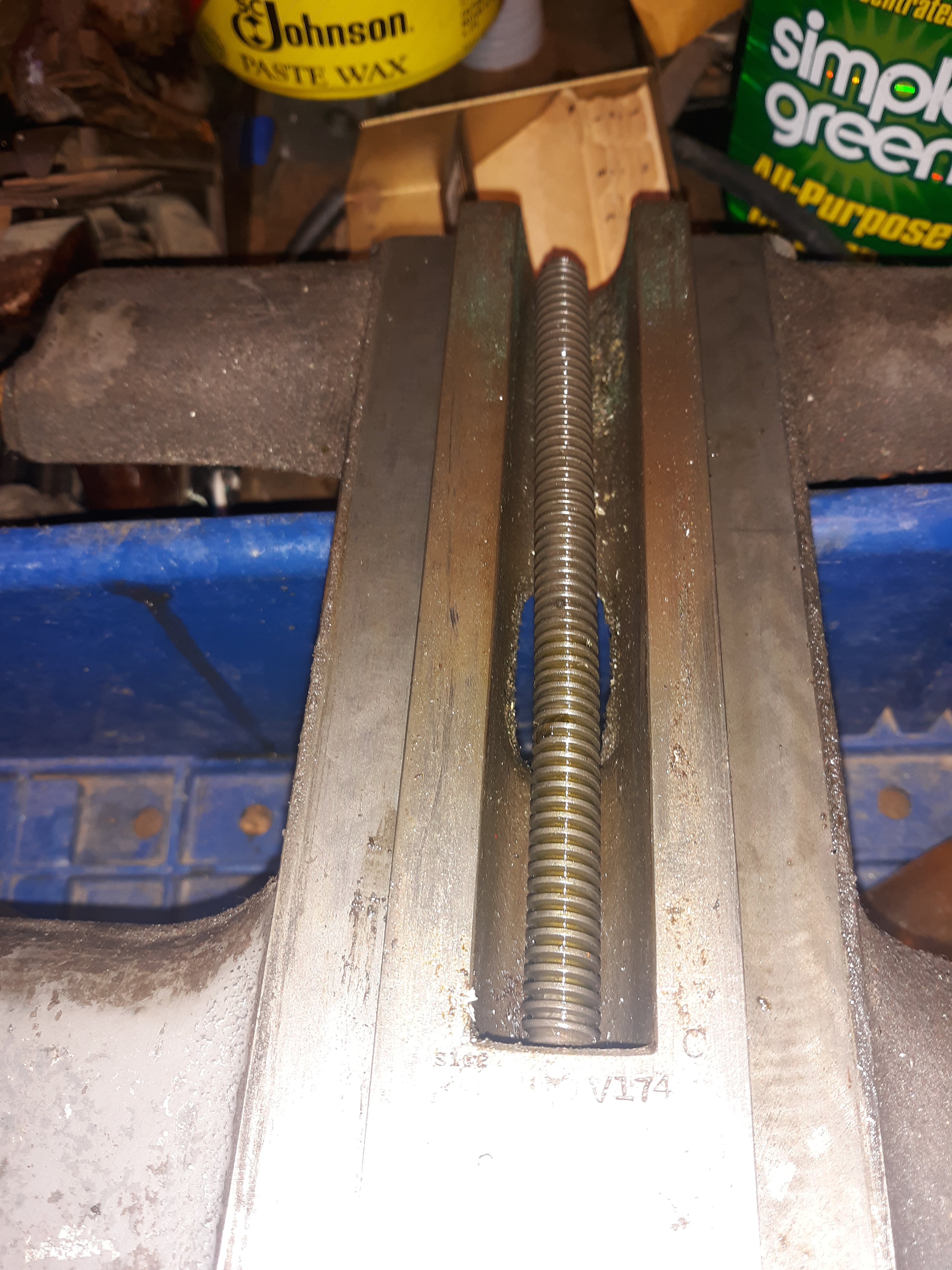

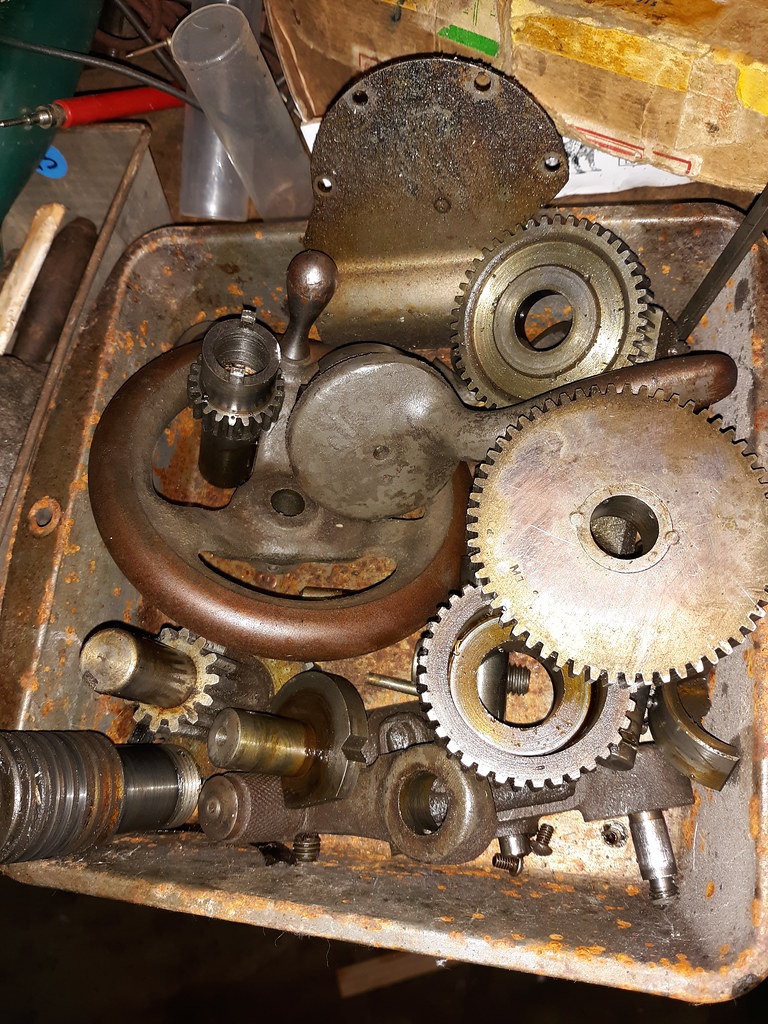

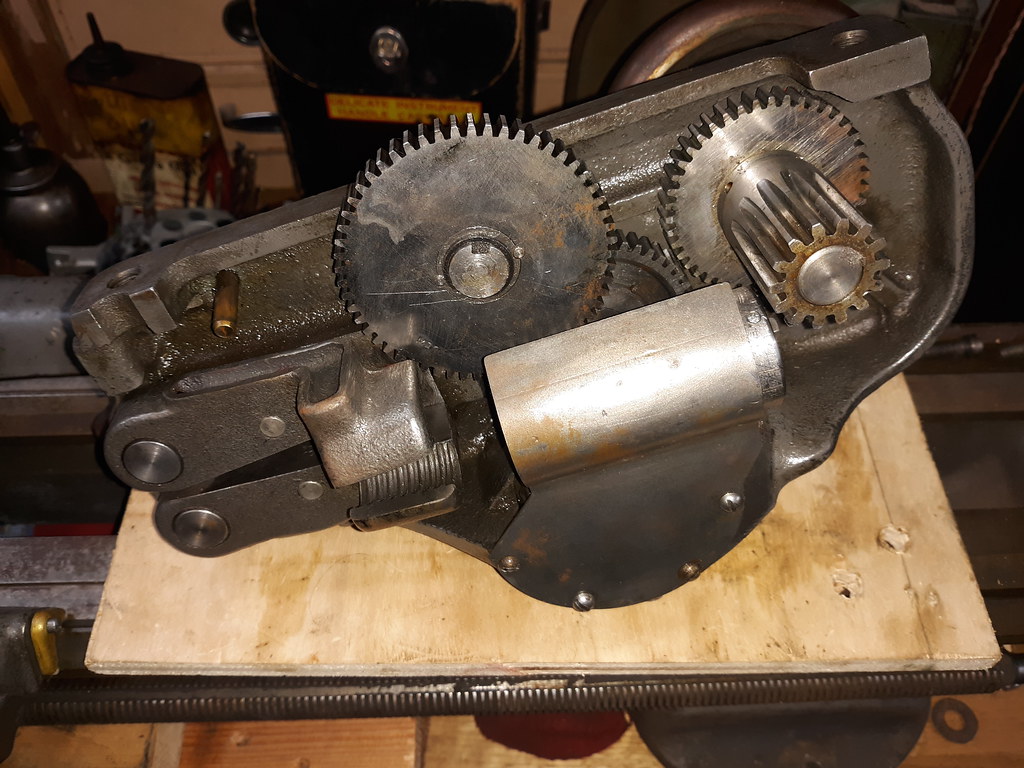

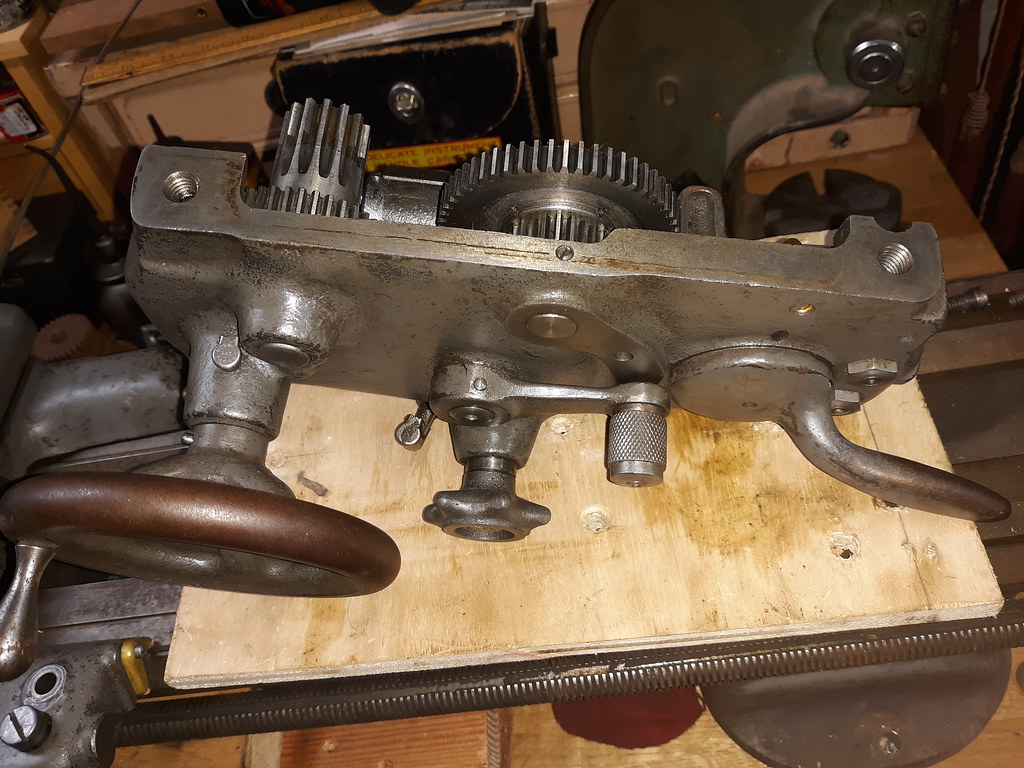

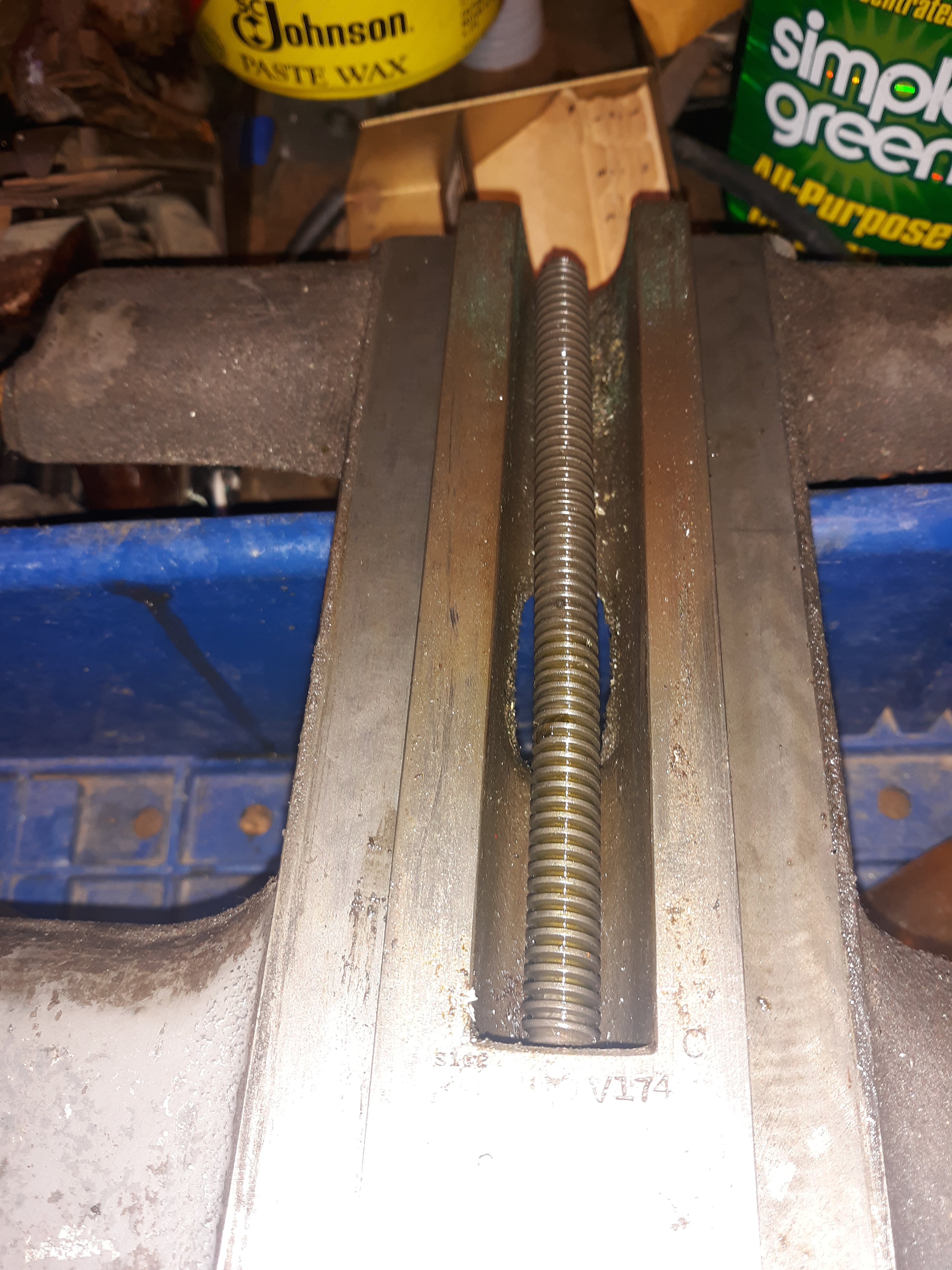

Anyway, I started pulling apart the carriage last night, and found a bent cross slide screw:

I am not too surprised by that, as the cross slide base was broken off a couple inches from the end. I have another, thanks to my friend Jabber, but I do need to source another screw. Also, the lace up belt I had sitting around is about 3-4 inches too short. So it goes.

Until next time.