- Joined

- Apr 13, 2021

- Messages

- 26

Hello,

First off, let me know if this is the wrong section for this, or maybe I should double post in the Asian Lathes section?

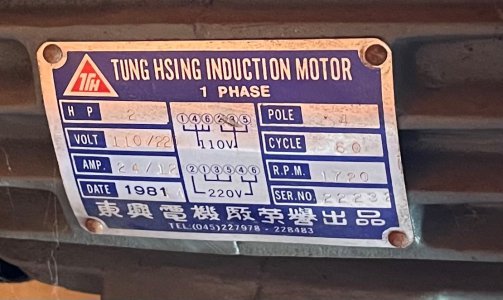

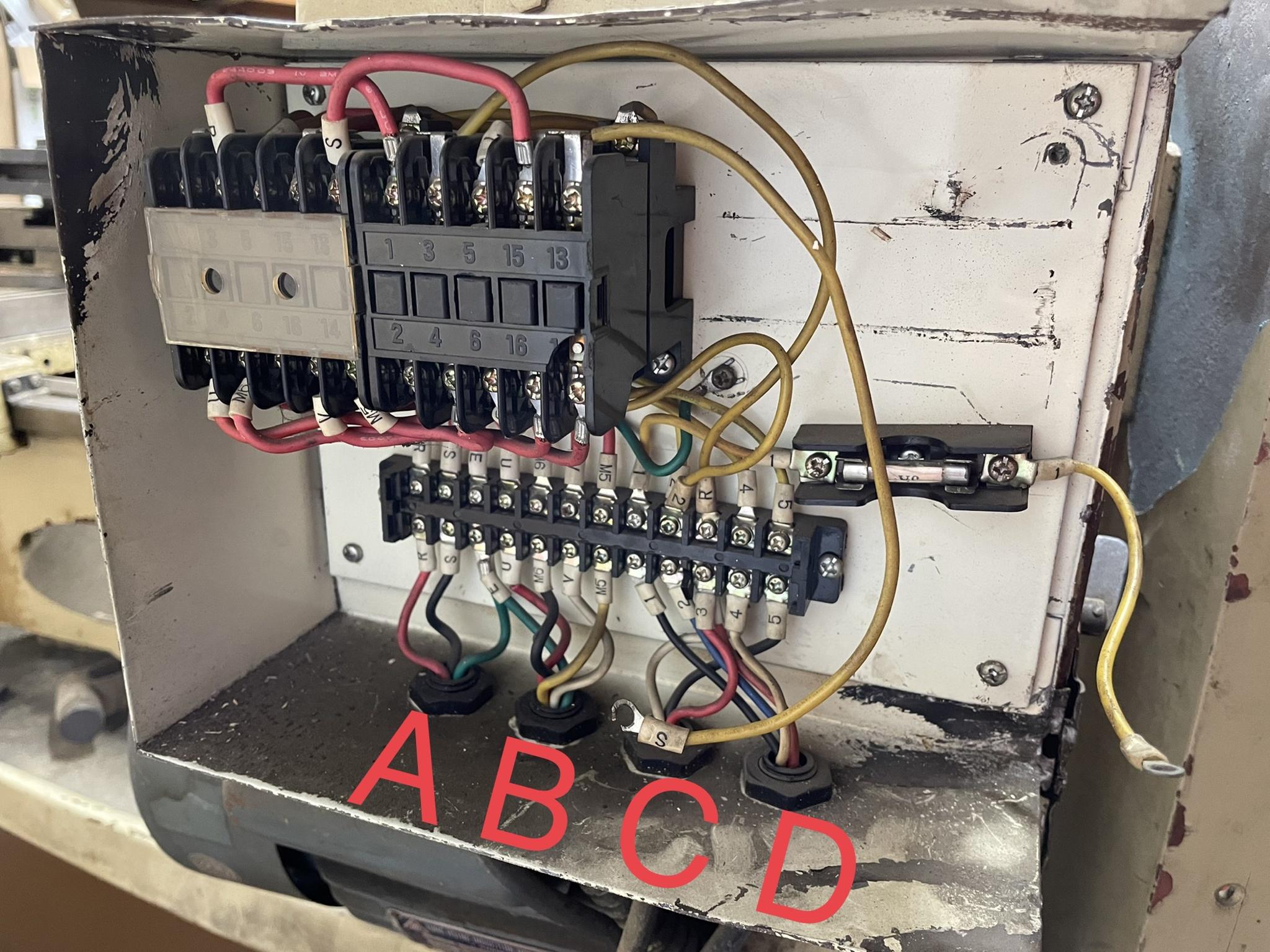

Anyways, I recently acquired a 1984 Crown lathe I am attempting to revive. It seems to be similar to the Honden/Jet lathes of this era. Unfortunately some of the wiring to the magnetic contactors isn’t complete. Would anyone with a similar lathe be willing to upload a picture of their wiring box?

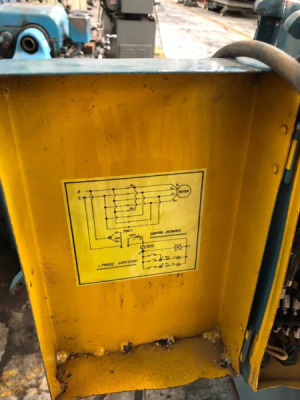

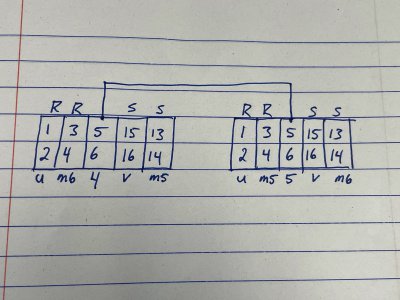

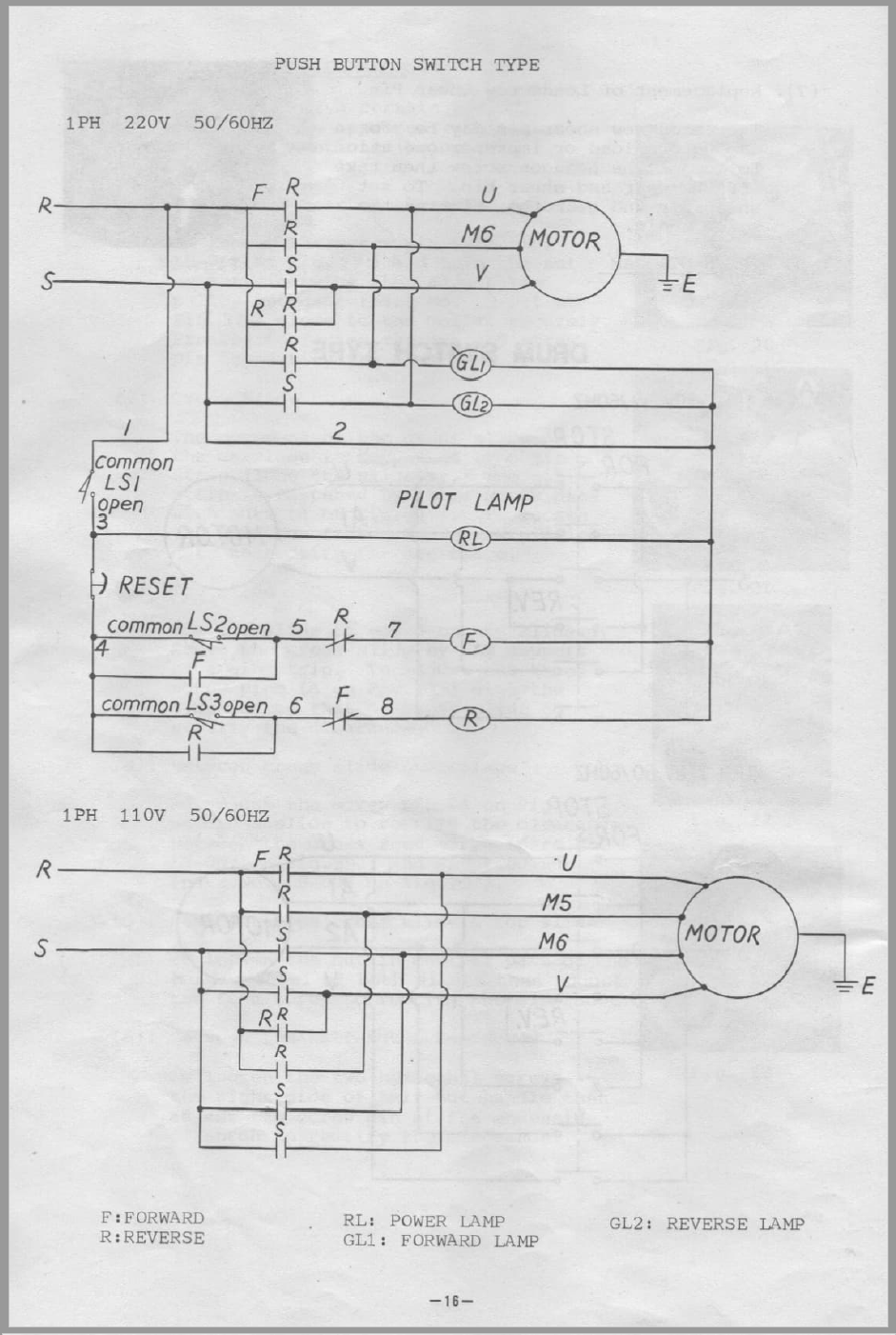

I found a Honden wiring diagram that seems accurate, but I am uncertain which pole controls the coil. The side terminals or maybe 13/14?

Also....in the picture, I labeled the conduits. I'm not sure I understand the role of "C"; it leads to a box under the power feed.

A: 110V in

B: Motor

C: Unknown

D: Power control (emergency stop)

Thanks,

Alex

First off, let me know if this is the wrong section for this, or maybe I should double post in the Asian Lathes section?

Anyways, I recently acquired a 1984 Crown lathe I am attempting to revive. It seems to be similar to the Honden/Jet lathes of this era. Unfortunately some of the wiring to the magnetic contactors isn’t complete. Would anyone with a similar lathe be willing to upload a picture of their wiring box?

I found a Honden wiring diagram that seems accurate, but I am uncertain which pole controls the coil. The side terminals or maybe 13/14?

Also....in the picture, I labeled the conduits. I'm not sure I understand the role of "C"; it leads to a box under the power feed.

A: 110V in

B: Motor

C: Unknown

D: Power control (emergency stop)

Thanks,

Alex