- Joined

- Apr 13, 2021

- Messages

- 26

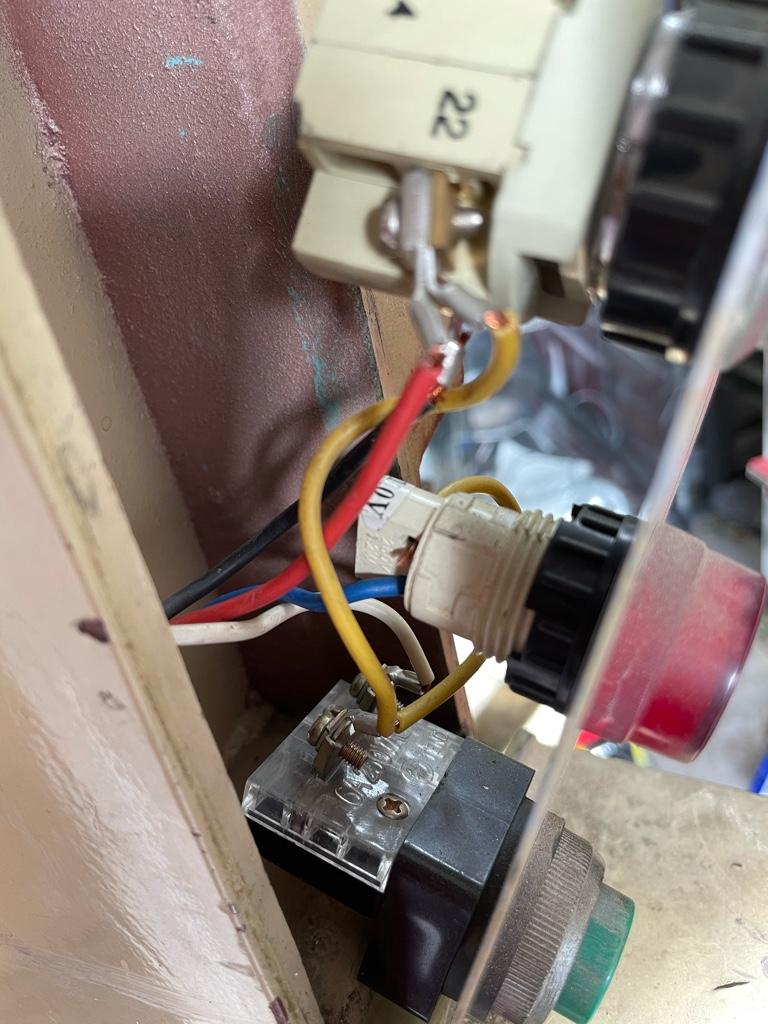

Yes, I removed all wiring to the coils. I kind of thought the same, but my Fluke read 77.7 on both coils, not even a marginal difference between the two. Maybe they're bad?I just reposted- check post #18 again

Last edited: