- Joined

- Nov 24, 2014

- Messages

- 3,164

Thanks for the reply.

Some how I had the idea that you planned on mounting cabinets to the walls. Maybe that was someone else or I just imagined it. Anyway, no fear with just tool boards.

The latest floor plan solves my saw/stock length issue too.

I should have mentioned before, your bridge crane will be a joy every time you use it. You're doing a great job.

Some how I had the idea that you planned on mounting cabinets to the walls. Maybe that was someone else or I just imagined it. Anyway, no fear with just tool boards.

The latest floor plan solves my saw/stock length issue too.

I should have mentioned before, your bridge crane will be a joy every time you use it. You're doing a great job.

I had decided against cabinets since the container is so small, I didn't want to make it feel any smaller by having cabinets at eye level. I also have a way of mounting brackets to the H beams to mount heavy items so I don't have to mount anything heavy on the walls although I am really trying to keep the walls clean.

I had decided against cabinets since the container is so small, I didn't want to make it feel any smaller by having cabinets at eye level. I also have a way of mounting brackets to the H beams to mount heavy items so I don't have to mount anything heavy on the walls although I am really trying to keep the walls clean.

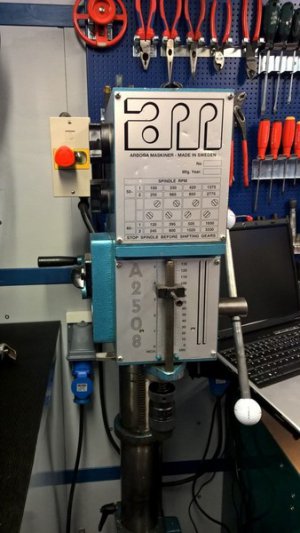

The receptacles are the 3 phase outlets and they are not that expensive - about 12 USD. We have a store here called Biltema where they sell most of this stuff and nearly everything is made in China hence the low price. I also bought the tool boards there. The boards are high gloss enamel paint on sheet metal and there are a large number of different brackets and shelves available for the boards which is why I went with this solution - and also because it is reasonably cheap by Norwegian standards.

The receptacles are the 3 phase outlets and they are not that expensive - about 12 USD. We have a store here called Biltema where they sell most of this stuff and nearly everything is made in China hence the low price. I also bought the tool boards there. The boards are high gloss enamel paint on sheet metal and there are a large number of different brackets and shelves available for the boards which is why I went with this solution - and also because it is reasonably cheap by Norwegian standards. I have also set up my old tool boards so I no longer need to search for my most commonly used tools.

I have also set up my old tool boards so I no longer need to search for my most commonly used tools.

I am of course buying it secondhand and will likely mount it on a cabinet. I'll post more pictures of the RPC and bench tops when I get back from church.

I am of course buying it secondhand and will likely mount it on a cabinet. I'll post more pictures of the RPC and bench tops when I get back from church.