- Joined

- Apr 1, 2013

- Messages

- 1,142

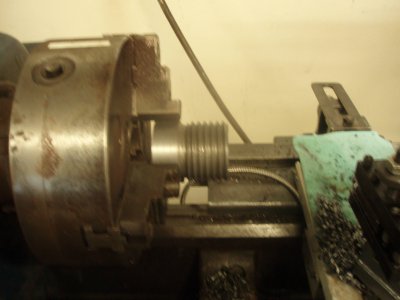

Arm,

do you have a metric lead screw If so it will be pretty easy. you just have to follow the change gear charts for the pitch and remeber to reingage the cariage at the right point on the dial. it is good practise to make a light cut on the first pass and check the pitch with a guage. this way if you are off youcan fix it without messing up the part.

And remember if you don't screw up once in a while you aren't doing anything

do you have a metric lead screw If so it will be pretty easy. you just have to follow the change gear charts for the pitch and remeber to reingage the cariage at the right point on the dial. it is good practise to make a light cut on the first pass and check the pitch with a guage. this way if you are off youcan fix it without messing up the part.

And remember if you don't screw up once in a while you aren't doing anything

Good effort Larry

That's our next big hurdle we want to tackle on our Machine.

Never did any so reckon now is the time better than any other

Except ours will be in Metric

regards

aRM