- Joined

- Jun 17, 2012

- Messages

- 2,220

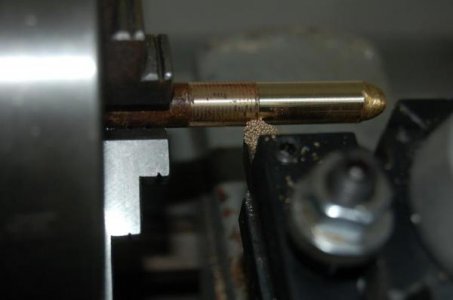

Today I made these three adjuster nuts for my Aloris tool holders. I only needed 2 but figured, while I'm at it, may as well make an extra. The photo shows an original at the top and the 3 that I made. Mine are better! The threads are nice and snug and I made them about .075" thicker so that they won't rock on the stud.