Hi outsider347,

Maybe someone with good electrical knowledge/experience will chime in on this, mine is very limited. Anyway, this is what I ended up with and prolly a little overkill:

Sola SDP 2-24-100T Power Supply ~$25 + shipping

http://www.ebay.com/itm/Sola-SDP-2-24-100T-Power-Supply-Used-Nice-/261237583005

Even though you could use something as simple/cheap as a windshield wiper motor, I really like the brushless motor with the instant reverse feature. You can drive it nice and slow to just kiss the shoulder then reverse it out without crashing. hth, & post a pic when you're done k...

fwiw, if you find another Dunkermotoren, the wiring was easy enough even for me to do:

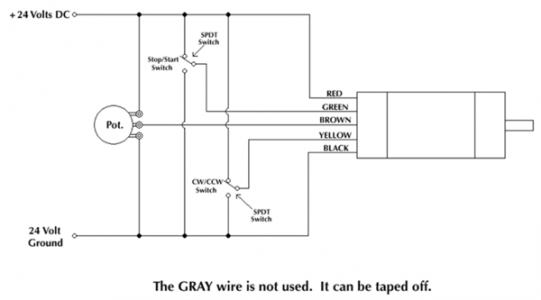

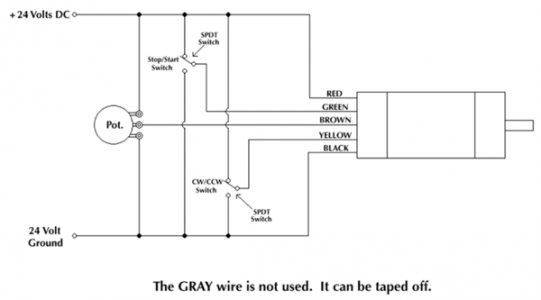

I asked someone how/where do you hook up the Jog switch and here is the pic they gave:

Sadly, the jog feature doesn't work, but like I said, my electrical knowledge is lacking...

Oh... the other stuff you'll need: 5k potentiometer, on/off switch + 2 SPDT switches (RadioShack?)

Where did you get the wiring diagram for the JOG switch? I don't see how it would work unless it simultaneously activated the Stop/Start switch.

That "JOG" circuit really looks like a "RAPID" circuit?

Ken