- Joined

- Jan 29, 2014

- Messages

- 156

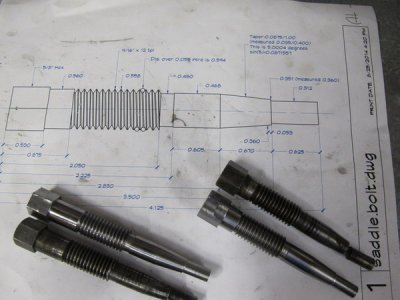

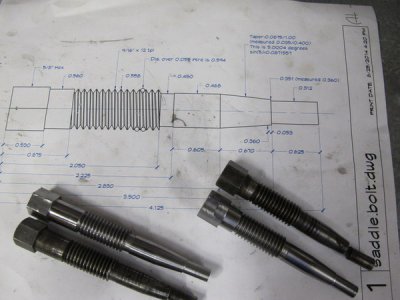

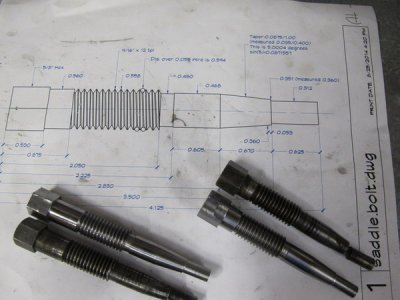

This is my first true project. Everything up to this point has been practice, but these will be going into my mill.

My Hardinge UM came with a couple of broken bolts. These lock the table rotation.

Did my best to take measurements off the existing bolts. Used 1146 and feel pretty good about getting the dimensions within 0.001.

They appear to fit and the table does not rotate, so I am declaring this a success.

My Hardinge UM came with a couple of broken bolts. These lock the table rotation.

Did my best to take measurements off the existing bolts. Used 1146 and feel pretty good about getting the dimensions within 0.001.

They appear to fit and the table does not rotate, so I am declaring this a success.