- Joined

- Sep 28, 2013

- Messages

- 4,306

great start Ryan, though it may be worth a thread of its own, particularly to make it easier for others to find.

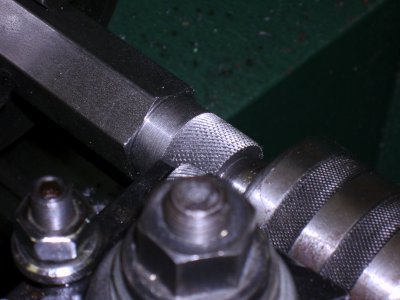

I've been cracking on trying to get stuff done before the start of the semester next week, so I've managed to fix a 1/2in Jacobs chuck and make tailstock arbor for it (forgot to take pic), screwed up and haven't yet fixed the Jacobs chuck on my DP (too embarrassed to post a pic) and ground a trepanning tool to cut out a hole from an alu blank which will be another clamp for my bike.

I needed a 40mm bore, so drilling up to 1/2in then boring the rest of the way would have taken ages, so I ground a trepanning tool and spent ages using that instead

now that I know it cuts like a grooving/ parting tool, I'll grind it a little thinner and cut a chip breaker so that both tips (not just the left one) cut, which should make it less painful to use. Pretty impressed that it worked at all to be honest. Bore is now 35mm, which was the biggest I could get without hitting the jaws behind the work.

I've been cracking on trying to get stuff done before the start of the semester next week, so I've managed to fix a 1/2in Jacobs chuck and make tailstock arbor for it (forgot to take pic), screwed up and haven't yet fixed the Jacobs chuck on my DP (too embarrassed to post a pic) and ground a trepanning tool to cut out a hole from an alu blank which will be another clamp for my bike.

I needed a 40mm bore, so drilling up to 1/2in then boring the rest of the way would have taken ages, so I ground a trepanning tool and spent ages using that instead

now that I know it cuts like a grooving/ parting tool, I'll grind it a little thinner and cut a chip breaker so that both tips (not just the left one) cut, which should make it less painful to use. Pretty impressed that it worked at all to be honest. Bore is now 35mm, which was the biggest I could get without hitting the jaws behind the work.